吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (5): 1806-1816.doi: 10.13229/j.cnki.jdxbgxb.20230825

• 农业工程·仿生工程 • 上一篇

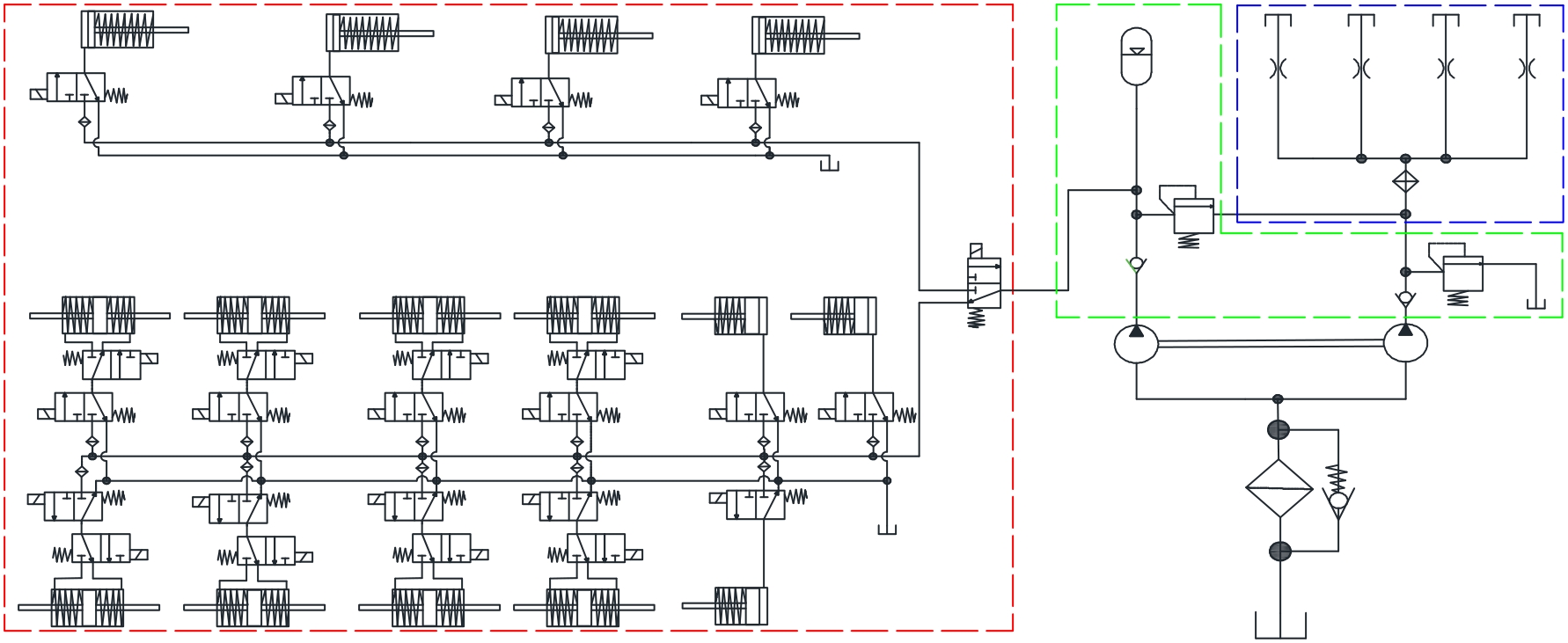

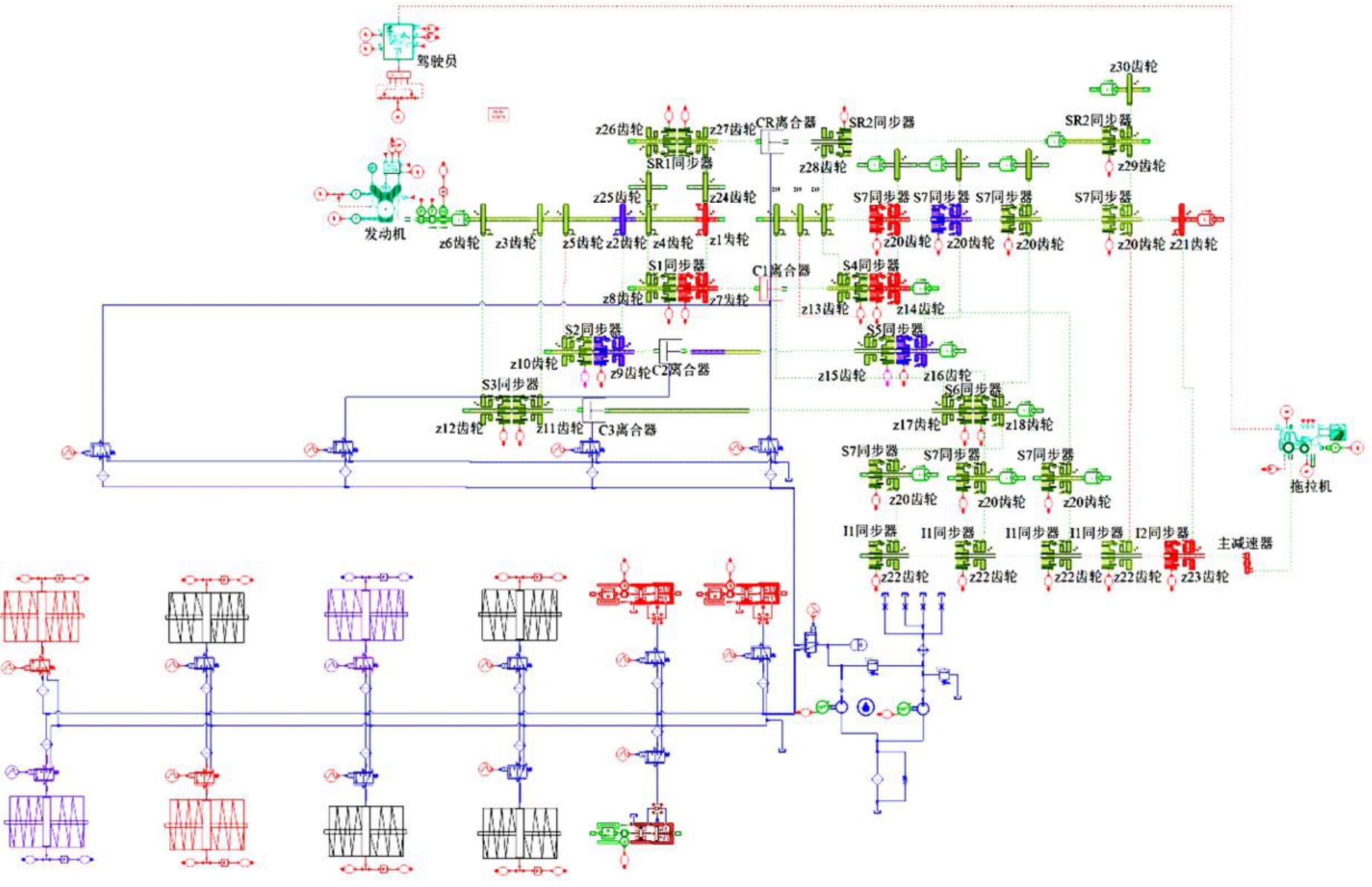

重型拖拉机新型双离合全动力换挡变速箱液压系统设计与试验

王建1,马文虎1,谢太林2,郭华2,尹必峰1

- 1.江苏大学 汽车与交通工程学院,江苏 镇江 212013

2.江苏常发农业装备股份有限公司研究院,江苏 常州 213000

Design and test of hydraulic system for new dual-clutch full-powershift transmission of heavy-duty tractor

Jian WANG1,Wen-hu MA1,Tai-lin XIE2,Hua GUO2,Bi-feng YIN1

- 1.School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

2.Changzhou Changfa Technology Development Co. ,Ltd. ,Changzhou 213000,China

摘要:

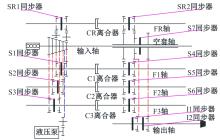

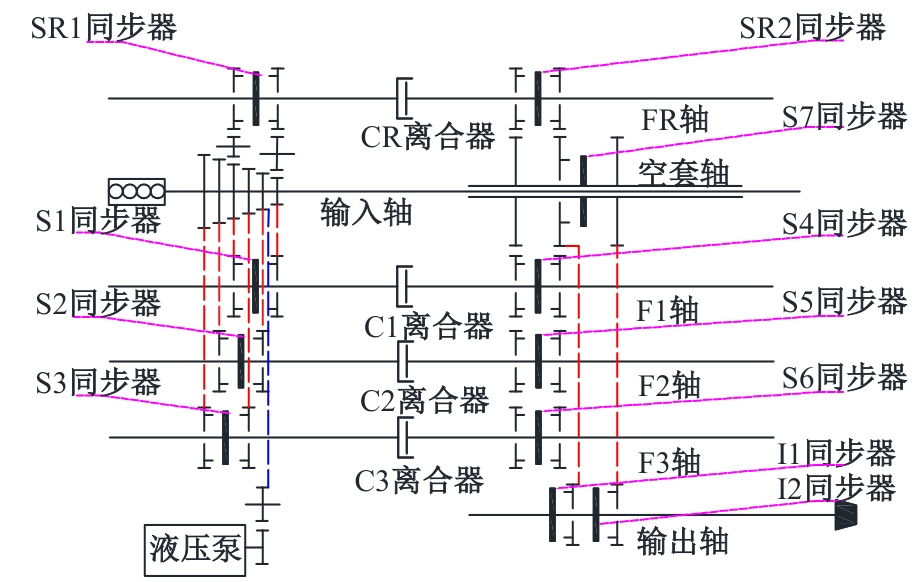

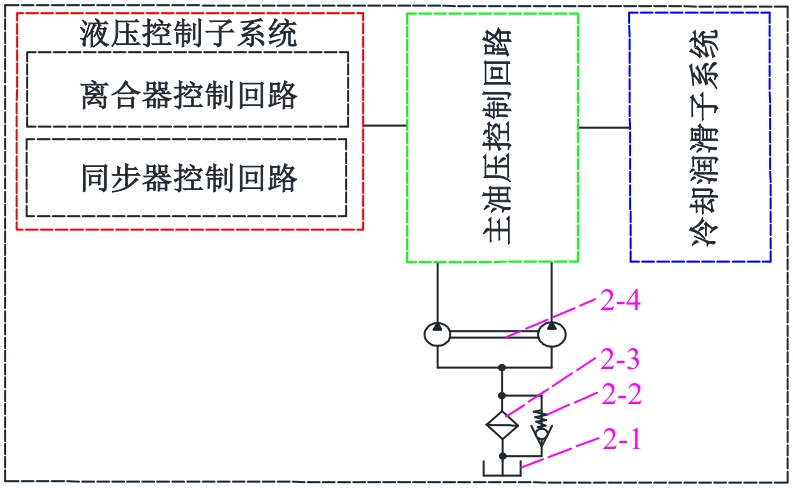

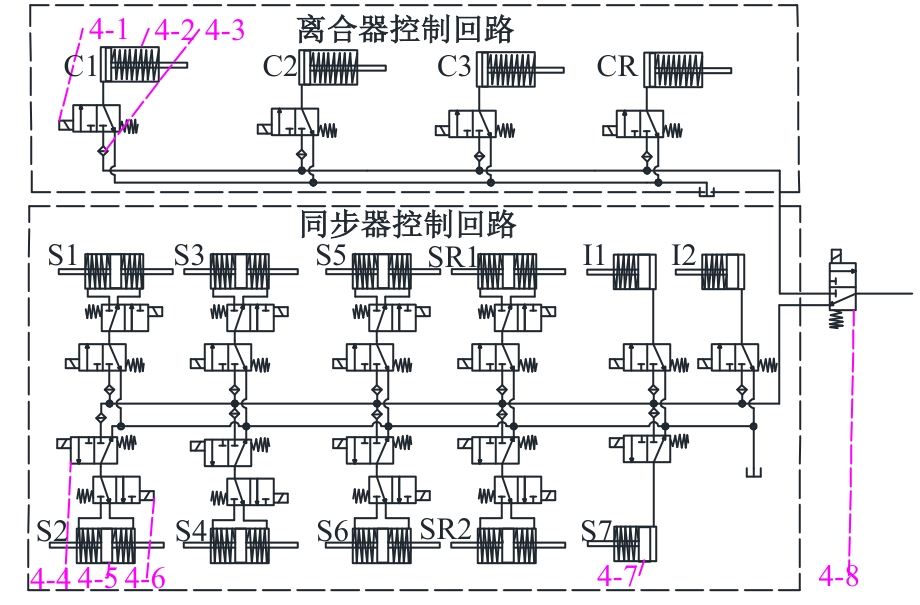

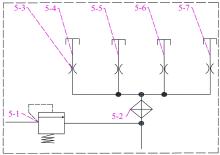

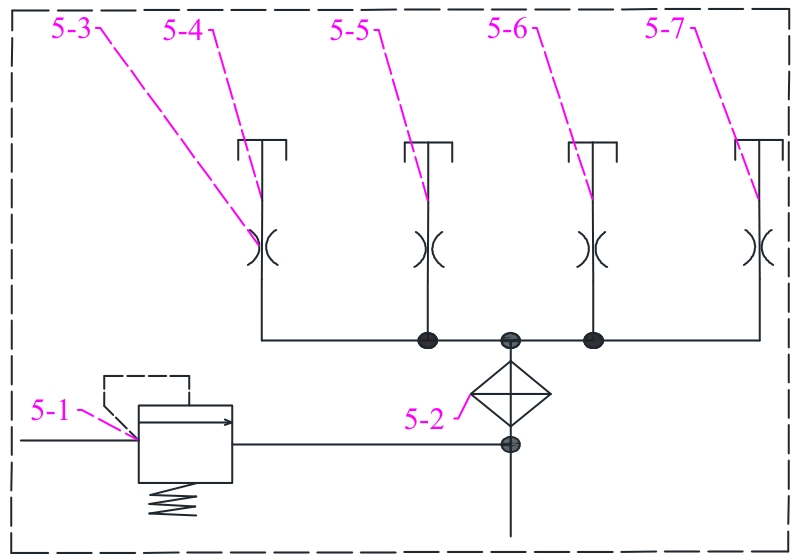

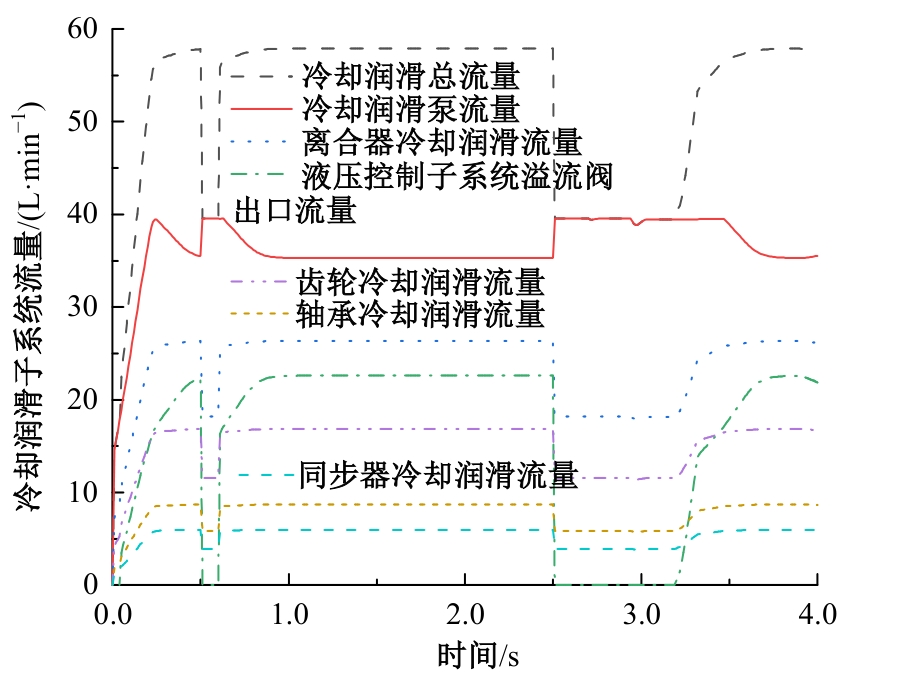

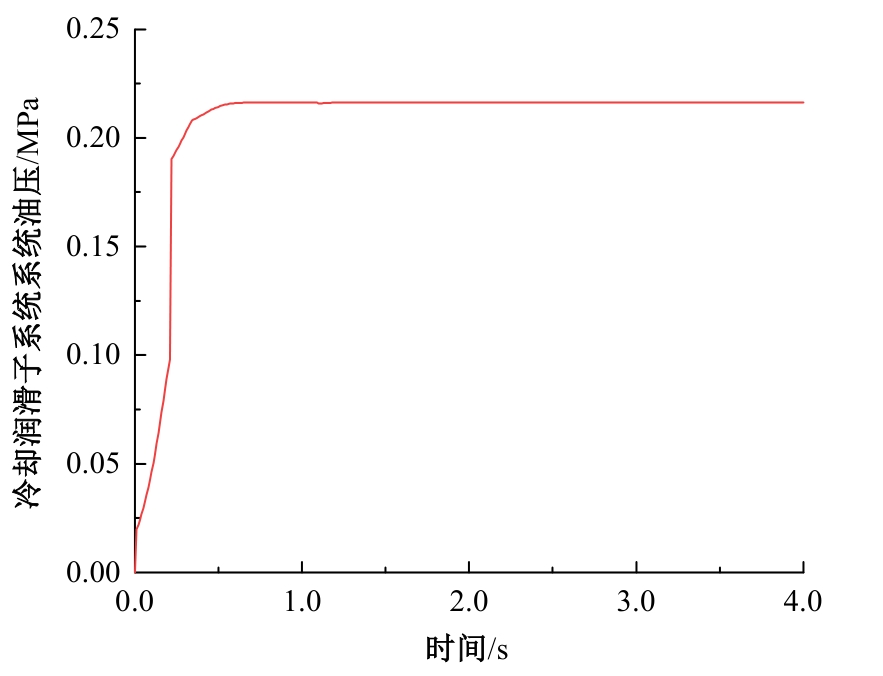

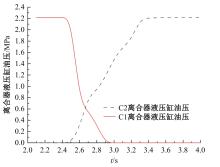

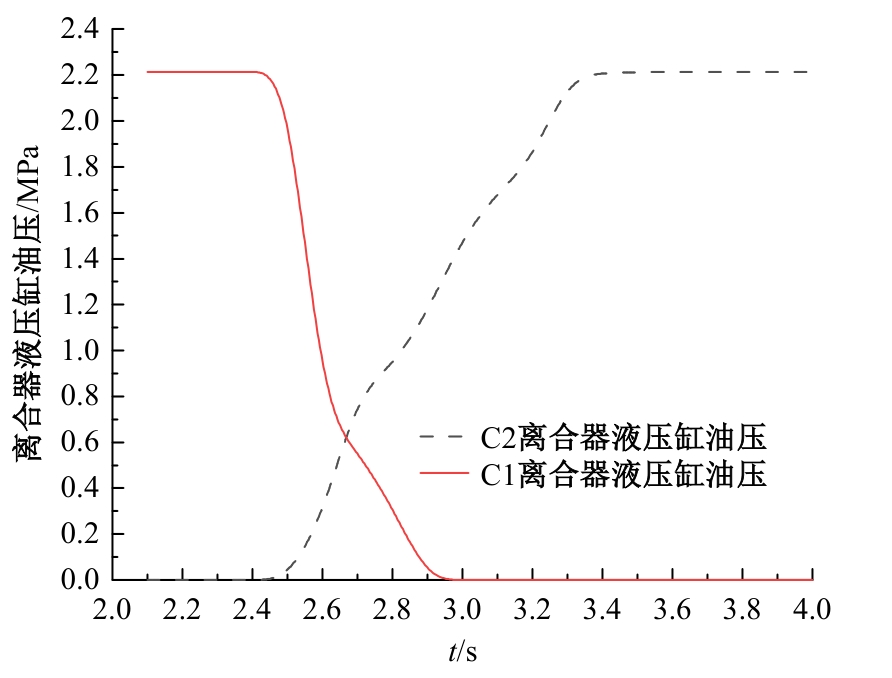

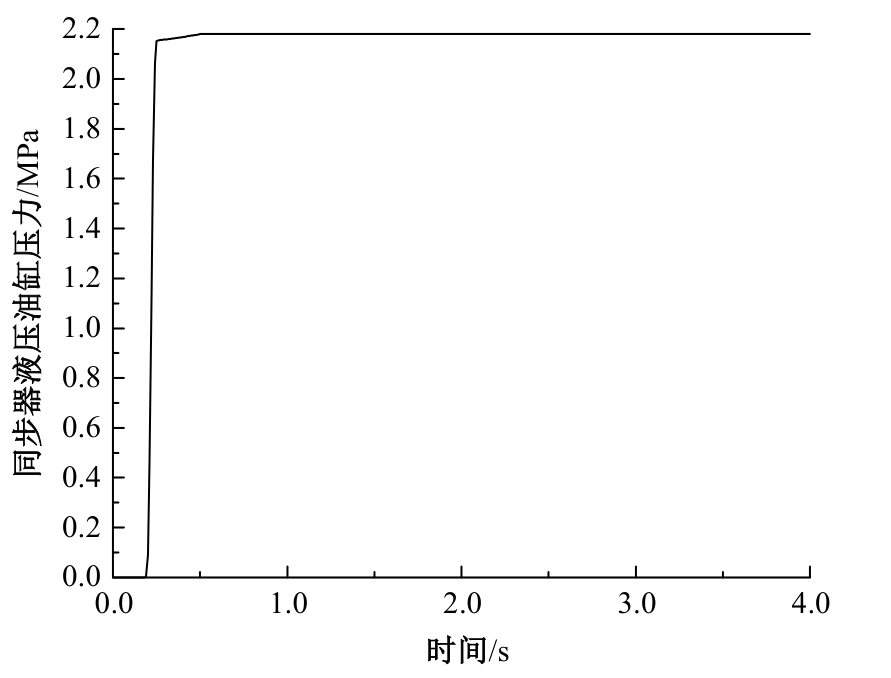

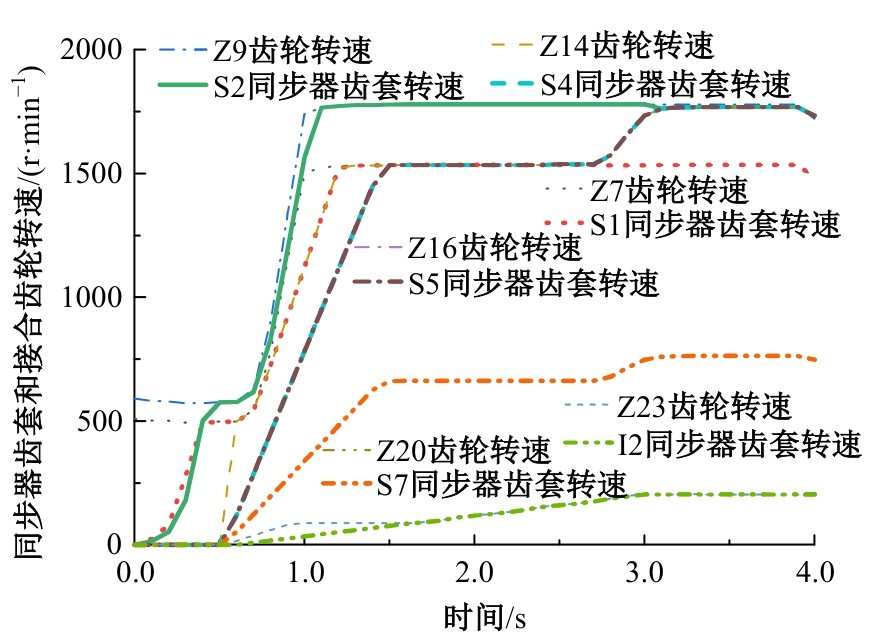

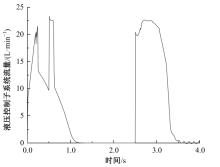

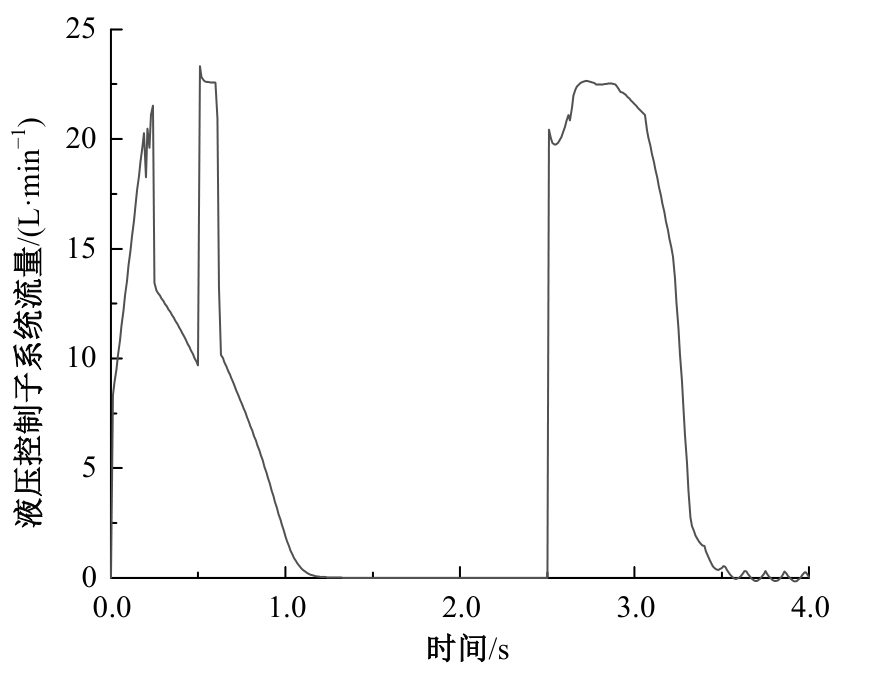

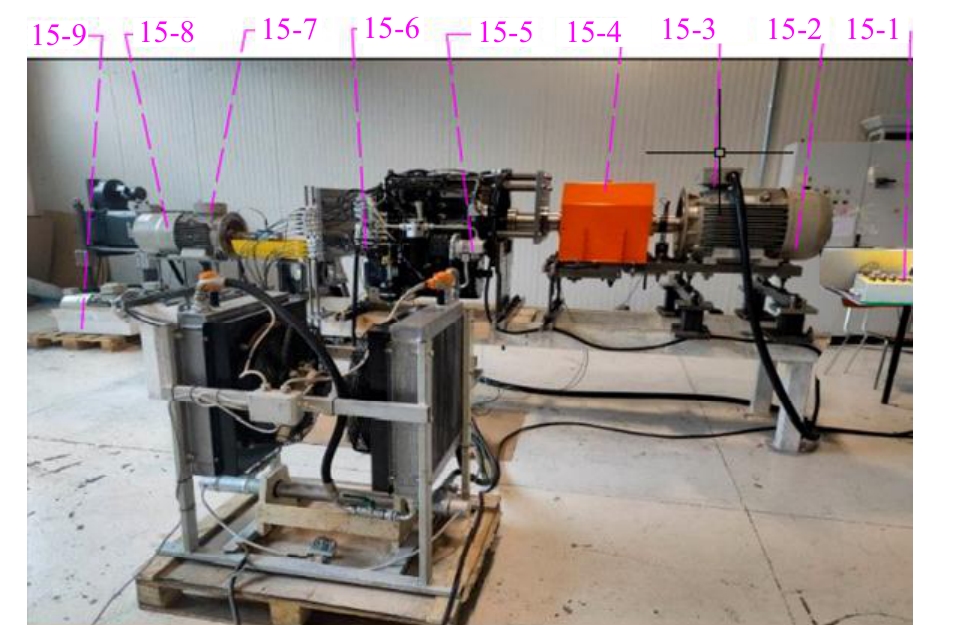

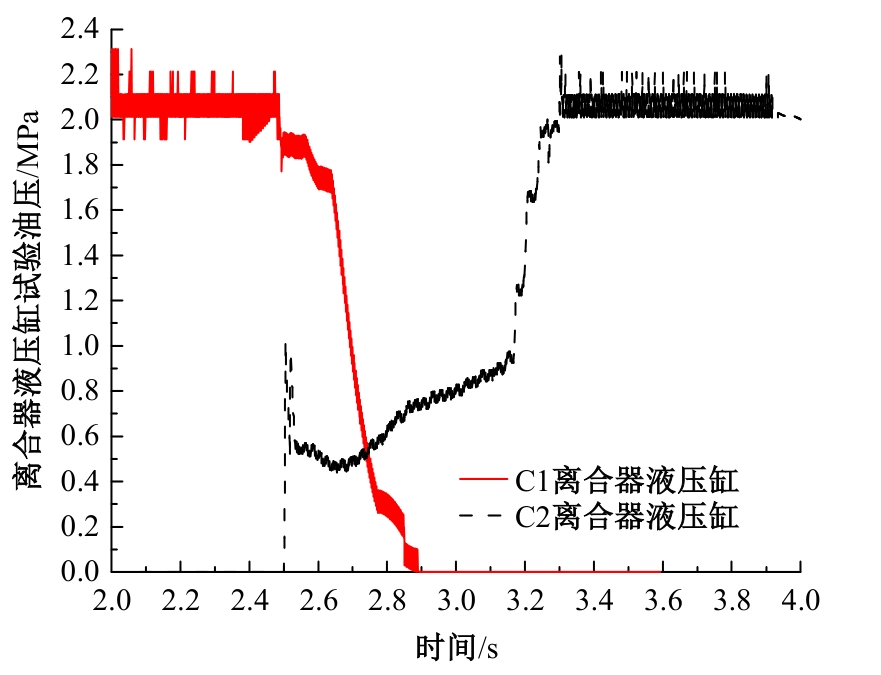

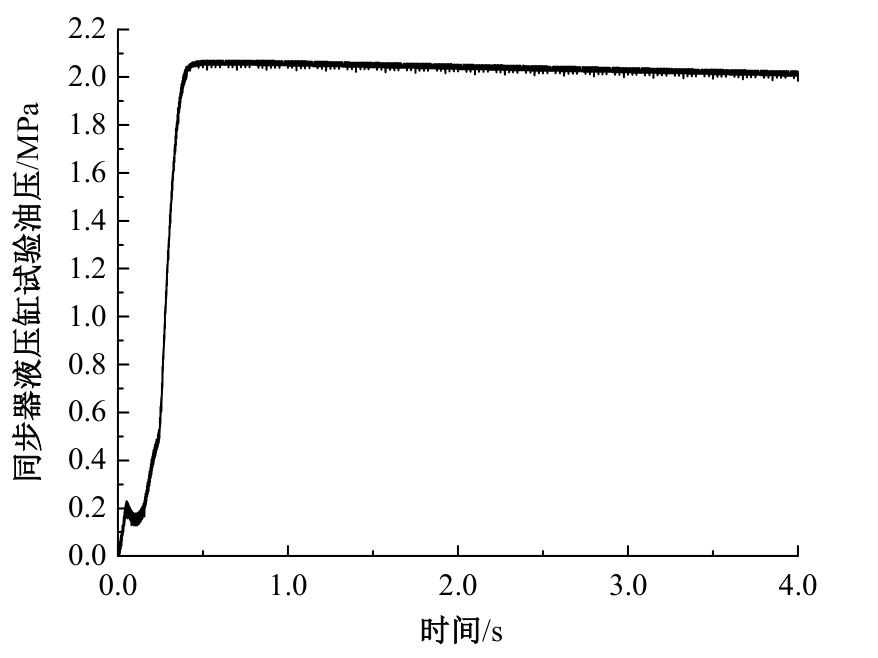

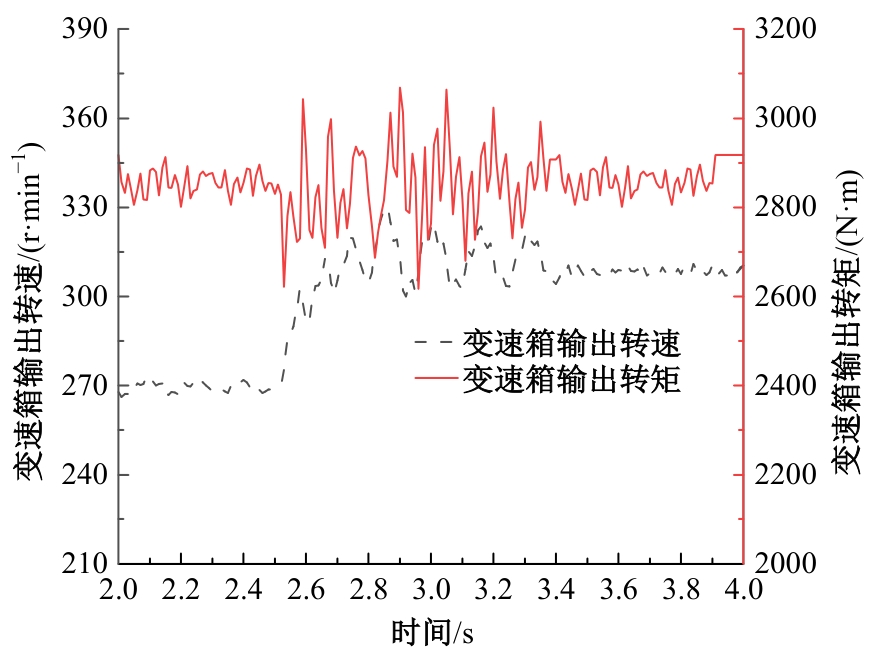

设计了用于全新开发223.7 kW(300 hp)重型拖拉机新型双离合全动力换挡变速箱的液压系统,以达到换挡动力不中断和变速箱冷却润滑的目的。建立了AMESim动力换挡仿真模型,分析了液压系统流量、油压特性和换挡过程离合器与同步器的动态特性。仿真结果表明:离合器液压缸建压时间少于1 s,泄压时间少于0.6 s,建压/泄压时压力稳定;同步器液压缸在0.3 s内建立稳定油压;冷却润滑子系统用时0.5 s建立0.22 MPa稳定油压,最大流量为57.6 L/min;离合器在换挡过程中完成动力的平稳过渡,同步器在换挡之前完成预选挡。搭建了新型双离合全动力换挡变速箱试验台架进一步验证,离合器和同步器液压缸油压试验结果与仿真结果基本一致,变速箱输出转速从270 r/min上升至310 r/min,最大波动量为31 r/min,变速箱输出转矩稳定在2 910 N·m附近,最大波动量为稳定值的10.1%,换挡过程无动力中断。仿真和试验结果验证了液压系统可以满足重型拖拉机新型双离合全动力换挡变速箱的工作需求,本文工作可为重型拖拉机双离合全动力换挡变速箱液压系统设计和计算提供参考和指导。

中图分类号:

- TK5

| [1] | 席志强, 周志立, 张明柱, 等. 拖拉机动力换挡变速器换挡特性与控制策略研究[J]. 农业机械学报, 2016, 47(11): 350-357. |

| Xi Zhi-qiang, Zhou Zhi-li, Zhang Ming-zhu, et al. Shift characteristics and control strategy of power shift transmission on tractor[J]. Transactions of the Chinese Society of Agricultural Machinery, 2016, 47(11): 350-357. | |

| [2] | 傅生辉, 顾进恒, 李臻, 等. 基于MFAPC的动力换挡变速箱湿式离合器压力控制方法[J]. 农业机械学报, 2020, 51(12): 367-376. |

| Fu Sheng-hui, Gu Jin-heng, Li Zhen, et al. Pressure control method of wet clutch for PST of high-power tractor based on MFAPC algorithm[J]. Transactions of the Chinese Society of Agricultural Machinery, 2020, 51(12): 367-376. | |

| [3] | 谢斌, 武仲斌, 毛恩荣. 农业拖拉机关键技术发展现状与展望[J]. 农业机械学报, 2018, 49(8): 1-17. |

| Xie Bin, Wu Zhong-bin, Mao En-rong. Development and prospect of key technologies on agricultural tractor[J]. Transactions of the Chinese Society of Agricultural Machinery, 2018, 49(8): 1-17. | |

| [4] | 董春红. 简述拖拉机传动系统关键技术[J]. 拖拉机与农用运输车, 2022, 49(3): 9-13. |

| Dong Chun-hong. Analysis of tractor transmission system key technologies[J]. Tractor&Farm Transporter, 2022, 49(3): 9-13. | |

| [5] | 王韦韦, 陈黎卿, 杨洋, 等. 农业机械底盘技术研究现状与展望[J]. 农业机械学报, 2021, 52(8): 1-15. |

| Wang Wei-wei, Chen Li-qing, Yang Yang, et al. Development and prospect of agricultural machinery chassis technology[J]. Transactions of the Chinese Society of Agricultural Machinery, 2021, 52(8): 1-15. | |

| [6] | 袁哲, 臧宏达, 马文星, 等.变速箱润滑油路仿真分析及结构优化[J]. 吉林大学学报: 工学版, 2020, 50(4): 1257-1264. |

| Yuan Zhe, Zang Hong-da, Ma Wen-xing, et al. Simulation analysis structure optimization of lubrication oil circuit of gearbox[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(4): 1257-1264. | |

| [7] | Ma K, Sun D, Sun G, et al. Design and efficiency analysis of wet dual clutch transmission decentralised pump-controlled hydraulic system[J]. Mechanism and Machine Theory, 2020, 154:No.104003. |

| [8] | Lei Y L, Li X Z, Liang W P. Hydraulic system optimization and dynamic characteristic simulation of double clutch transmission[J]. Procedia Environmental Sciences, 2011, 10: 1065-1070. |

| [9] | 李磊. 新型选择性输出双离合自动变速器电液伺服控制系统设计[D]. 合肥: 合肥工业大学机械工程学院, 2015. |

| Li Lei. Design for electro-hydraulic servo control system of new dual-clutch transmission with selective output[D]. Hefei: School of Mechanical Engineering, Hefei University of Technology, 2015. | |

| [10] | 李春芾, 席军强, 刘春颖. 多片湿式离合器快充油过程影响因素分析与控制[J]. 中国机械工程, 2019, 30(5): 513-518. |

| Li Chun-fu, Xi Jun-qiang, Liu Chun-ying. Analyses and control influence factors for multi-plate wet clutches in fast oil filling processes[J]. China Mechanical Engineering, 2019, 30(5): 513-518. | |

| [11] | 王光明, 朱思洪, 史立新, 等. 拖拉机液压机械无级变速箱控制与交互系统[J]. 农业机械学报, 2015, 46(6): 1-7. |

| Wang Guang-ming, Zhu Si-hong, Shi Li-xin, et al. Control and interaction system for tractor hydro-mechanical CVT[J]. Transactions of the Chinese Society of Agricultural Machinery, 2015, 46(6): 1-7. | |

| [12] | 韩兵, 蔡忆昔, 张彤, 等. 强混合动力变速器液压系统设计与动态特性仿真[J]. 农业机械学报, 2011, 42(2): 43-47. |

| Han Bing, Cai Yi-xi, Zhang Tong, et al. Hydraulic system design and dynamic characteristic simulation of full hybrid transmission[J]. Transactions of the Chinese Society of Agricultural Machinery, 2011, 42(2): 43-47. | |

| [13] | 熊序, 鲁植雄, 程准, 等. 重型拖拉机液压机械无级变速箱冷却润滑油液的分配优化[J]. 南京农业大学学报, 2021, 44(5): 993-1001. |

| Xiong Xu, Lu Zhi-xiong, Cheng Zhun, et al. Oil distribution optimization of cooling and lubrication for hydro-mechanical continuously variable trans mission of heavy-duty tractor[J]. Journal of Nanjing Agricultural University,2021,44(5): 993-1001. | |

| [14] | 陆中华, 程秀生, 冯巍. 湿式双离合器自动变速器的升档控制[J]. 农业工程学报, 2010, 26(5): 132-136. |

| Lu Zhong-hua, Cheng Xiu-sheng, Feng Wei. Up-shift control in wet double clutch transmission[J]. Transactions of the CSAE, 2010, 26(5): 132-136. | |

| [15] | 孙冬野, 陈旭东, 李宝刚, 等. 基于遗传算法的拖拉机动力换挡过程动态控制方法[J]. 重庆大学学报, 2019, 42(8): 1-14. |

| Sun Dong-ye, Chen Xu-dong, Li Bao-gang, et al. Dynamic control method of tractor powershift process based on genetic algorithm[J]. Journal of Chongqing University, 2019, 42(8): 1-14. | |

| [16] | 陆凯, 鲁杨, 邓晓亭, 等. 理论换段点下HMCVT换段离合器转矩交接及控制[J]. 农业工程学报, 2022, 38(19): 23-32. |

| Lu Kai, Lu Yang, Deng Xiao-ting, et al. Torque handover and control of the HMCVT shift clutches under the theoretical shift condition[J]. Transactions of the CSAE, 2022, 38(19): 23-32. | |

| [17] | 孟彬, 杨冠政, 徐豪, 等. 插装式2D电液比例流量阀的特性研究[J]. 机械工程学报, 2022, 58(20): 421-437. |

| Meng Bin, Yang Guan-zheng, Xu Hao, et al. Study on characteristics of 2D cartridge electro-hydraulic proportional flow rate valve[J]. Journal of Mechanical Engineering, 2022, 58(20): 421-437. | |

| [18] | 李晓祥, 王安麟, 樊旭灿, 等. 面向离合器接合过程的比例电磁阀动态特性模型与设计[J]. 西安交通大学学报, 2020, 54(5): 46-52. |

| Li Xiao-xiang, Wang An-lin, Fan Xu-can, et al. Dynamic characteristics model and design of proportional solenoid valve for clutch engagement process[J]. Journal of Xi´an Jiaotong University, 2020, 54(5): 46-52. | |

| [19] | 任延飞, 席军强, 陈慧岩, 等. 湿式离合器先导式电液调压阀时频域建模与分析[J]. 兵工学报, 2023, 44(1): 222-232. |

| Ren Yan-fei, Xi Jun-qaing, Chen Hui-yan, et al. Time-frequency domain modeling and analysis of dynamic characteristics of pilot-operated electro-hydraulic pressure regulating value for wet clutch[J]. Acta Armamentarii, 2023, 44(1): 222-232. | |

| [20] | 李云燕, 刘宇键, 陈漫. 湿式离合器充油控制响应特性研究[J]. 机床与液压, 2022, 50(9): 184-189. |

| Li Yun-yan, Liu Yu-jian, Chen Man. Wet clutch oiling control response characteristics analysis[J]. Machine Tool & Hydraulics, 2022, 50(9): 184-189. | |

| [21] | Zhao J, Xiao M, Bartos P, et al. Dynamic engagement characteristics of wet clutch based on hydro-mechanical continuously variable transmission[J]. Journal of Central South University, 2021, 28(5): 1377-1389. |

| [22] | Lu T, Li H, Zhang J, et al. Supervisor control strategy of synchronizer for wet DCT based on online estimation of clutch drag torque[J]. Mechanical Systems and Signal Processing, 2016, 66: 840-861. |

| [23] | Li H, Lu T, Zhang J, et al. Modelling and analysis of the synchronization process for a wet dual-clutch transmission[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2015, 229(14): 1981-1995. |

| [24] | Walker P D, Zhang N. Engagement and control of synchroniser mechanisms in dual clutch transmissions[J]. Mechanical Systems and Signal Processing, 2012, 26: 320-332. |

| [1] | 商蕾,杨萍,杨祥国,潘建欣,杨军,张梦如. 基于APSO-BP-PID控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2024, 54(9): 2401-2413. |

| [2] | 张帆,韩宁,杜青,部竞琦,彭志军. MMH凝胶液滴蒸发与燃烧过程的数值仿真[J]. 吉林大学学报(工学版), 2024, 54(11): 3114-3124. |

| [3] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [4] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

| [5] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

| [6] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [7] | 罗勇,隋毅,申付涛,孙强,邓云霄,韦永恒. 基于双离合变速器的插电式混动系统起步控制策略[J]. 吉林大学学报(工学版), 2022, 52(12): 2765-2777. |

| [8] | 赵文伯,李玉洁,邓俊,李理光,吴志军. 针阀运动规律及其对喷嘴内流和喷雾特性影响[J]. 吉林大学学报(工学版), 2022, 52(10): 2234-2243. |

| [9] | 罗勇,韦永恒,黄欢,肖人杰,任淋,崔环宇. 驾驶员意图识别的P2.5插混构型双离合器起步控制[J]. 吉林大学学报(工学版), 2021, 51(5): 1575-1582. |

| [10] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

| [11] | 李志军,刘浩,张立鹏,李振国,邵元凯,李智洋. 过滤壁结构对颗粒捕集器深床过滤影响的模拟[J]. 吉林大学学报(工学版), 2021, 51(2): 422-434. |

| [12] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [13] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [14] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [15] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

|