吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (10): 3026-3037.doi: 10.13229/j.cnki.jdxbgxb.20211332

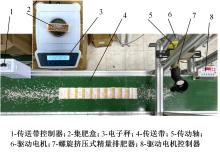

螺旋挤压式精量排肥器的仿真优化及试验

顿国强1( ),刘文辉1,吴星澎1,毛宁1,纪文义2,马洪岩3

),刘文辉1,吴星澎1,毛宁1,纪文义2,马洪岩3

- 1.东北林业大学 机电工程学院,哈尔滨 150040

2.东北农业大学 工程学院,哈尔滨 150030

3.黑龙江睿龙创新科技有限责任公司,哈尔滨 150050

Simulation optimization and experiment of screw extrusion precision fertilizer ejector

Guo-qiang DUN1( ),Wen-hui LIU1,Xing-peng WU1,Ning MAO1,Wen-yi JI2,Hong-yan MA3

),Wen-hui LIU1,Xing-peng WU1,Ning MAO1,Wen-yi JI2,Hong-yan MA3

- 1.College of Mechanical and Electrical Engineering,Northeast Forestry University,Harbin 150040,China

2.College of Engineering,Northeast Agricultural University,Harbin 150030,China

3.Heilongjiang Ruilong Innovation Technology Co. ,Ltd. ,Harbin 150050,China

摘要:

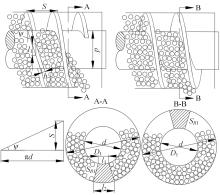

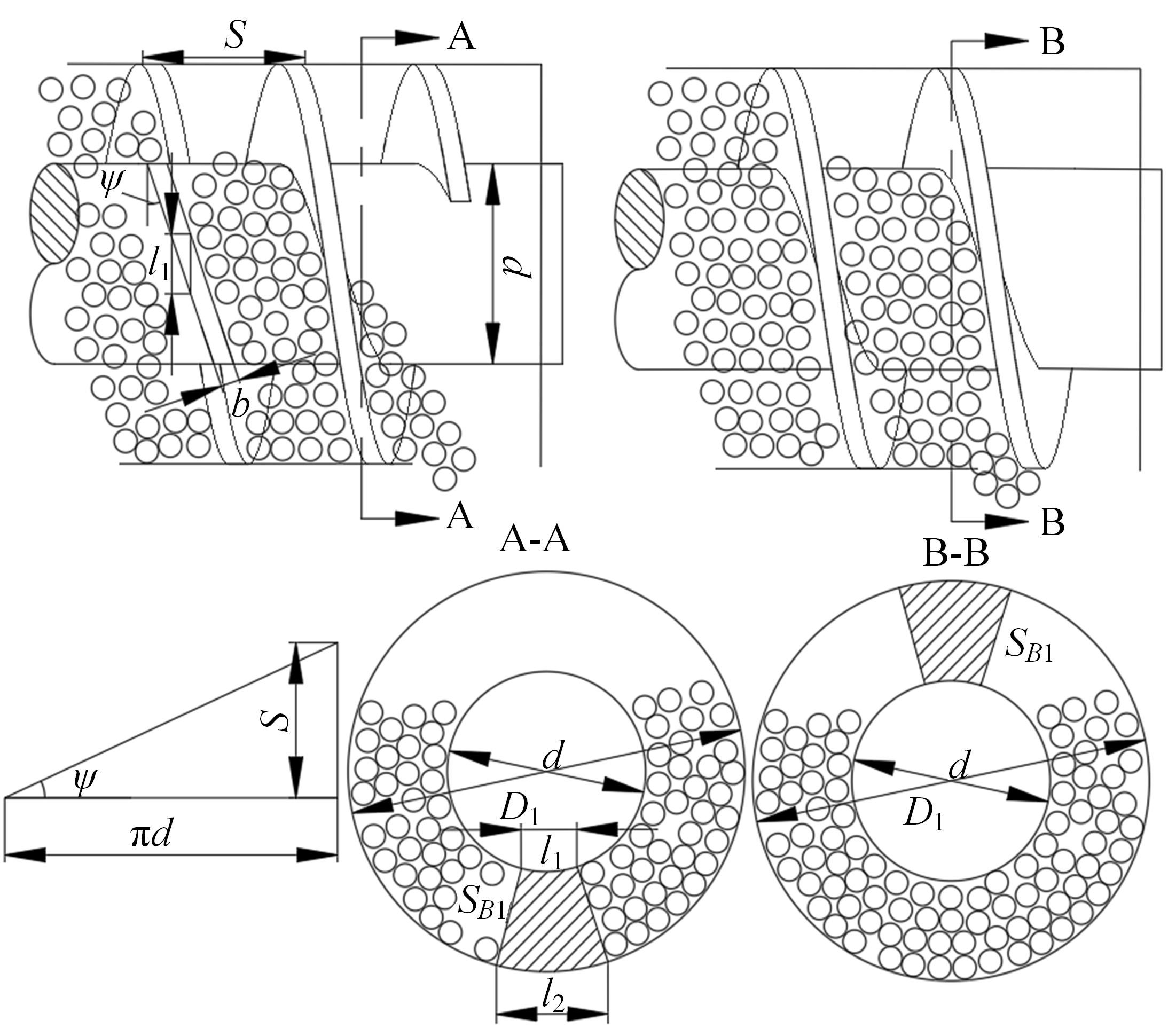

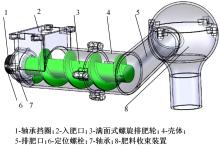

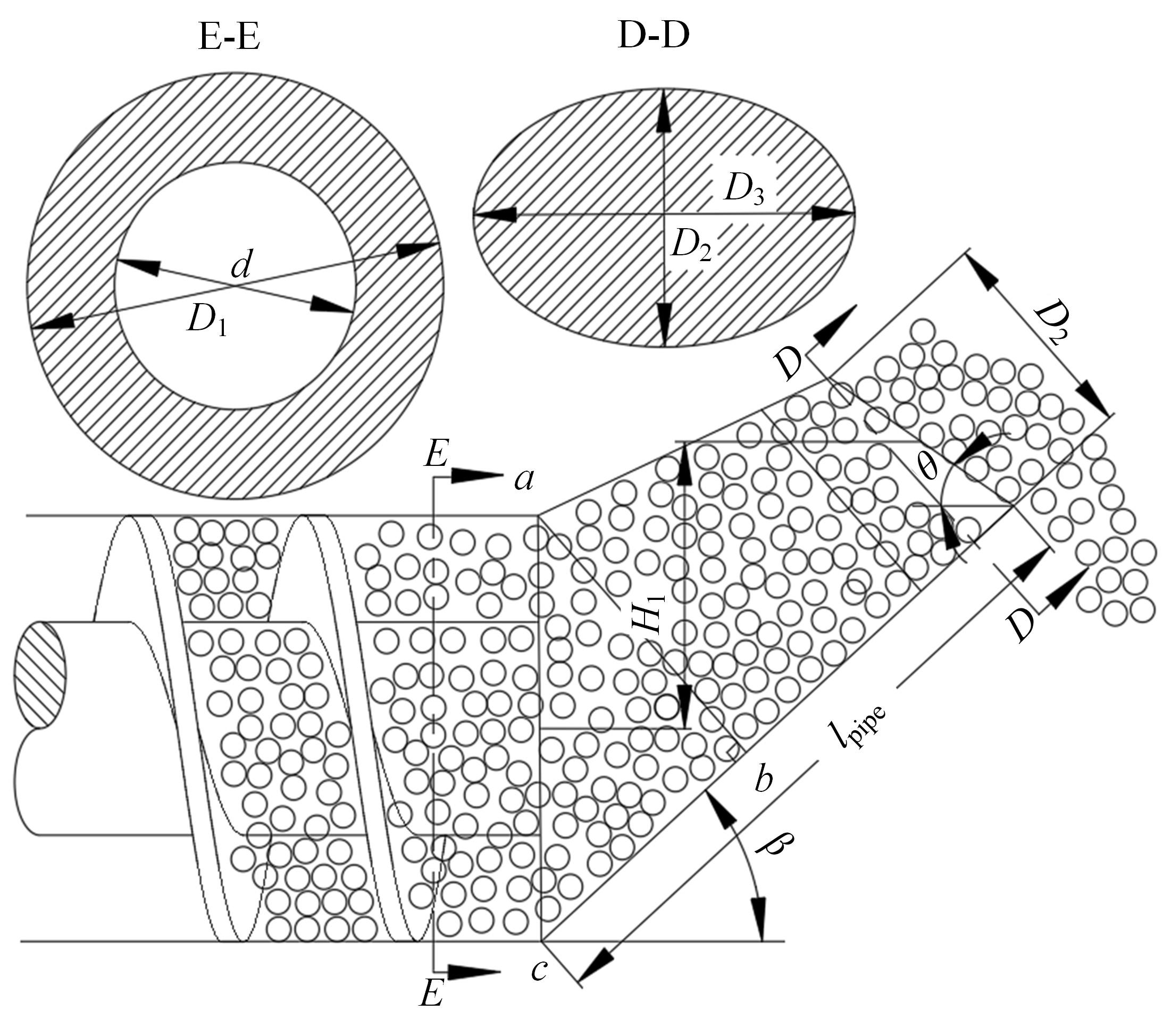

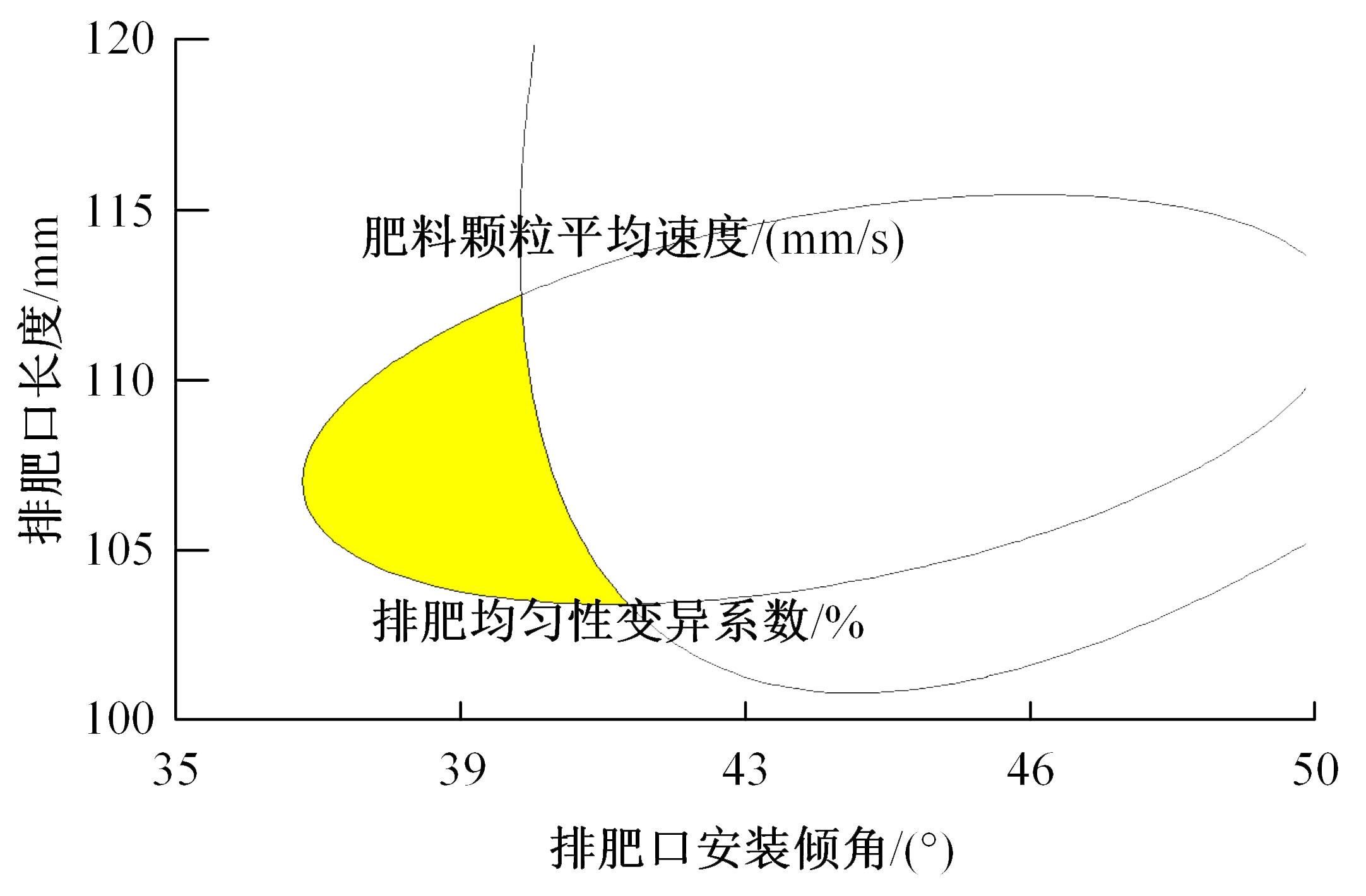

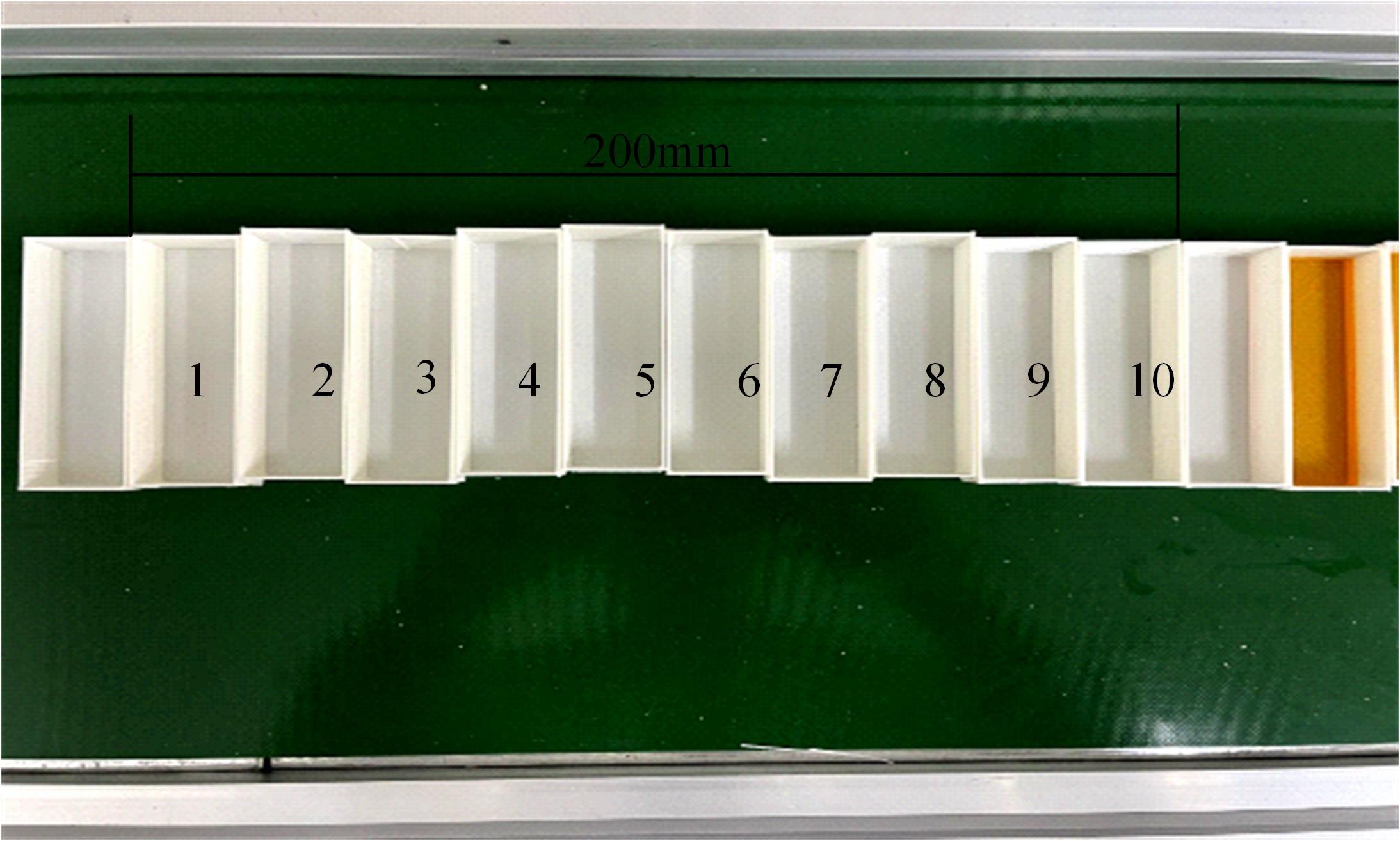

为满足现代农业精确定量施肥的需求,通过理论分析得出螺旋排肥器无法实现均匀排肥的原因,设计了一种基于采用肥料满充填螺旋挤压式输送原理的新型排肥器,通过理论分析得出影响排肥均匀性的参数,以排肥口安装倾角、排肥口长度为试验因素,以排肥均匀性变异系数与肥料颗粒平均速度为试验指标,设计了二因素五水平的二次通用旋转组合试验,试验结果表明:排肥口长度、排肥口安装倾角对排肥均匀性变异系数影响分别为极显著(P<0.01)、显著(0.01<P<0.05),排肥口安装倾角、排肥口长度对肥料颗粒平均速度影响为极显著(P<0.01),在排肥口安装倾角为40°、排肥口长度为105 mm时可获得排肥均匀性变异系数≤10%、肥料颗粒平均速度≥15.5 mm/s,在最优参数组合下进行台架验证试验与对比试验,台架试验与仿真试验相对误差分别为2.75%、1.75%,验证结果与仿真结果相一致。不同转速下挤压式螺旋排肥均匀性变异系数较单螺旋排肥器平均降低32.91%,不同转速下单圈排肥量平均降低6.70%,优化后的排肥器排肥均匀性好且排肥量损失较小。本研究可为螺旋排肥器的优化设计提供参考。

中图分类号:

- S147.2

| 1 | 高晶晶, 彭超, 史清华. 中国化肥高用量与小农户的施肥行为研究——基于1995~2016年全国农村固定观察点数据的发现[J]. 管理世界, 2019, 35(10): 120-132. |

| Gao Jing-jing, Peng Chao, Shi Qing-hua. Study on the high chemical fertilizers consumption and fertilization behavior of small rural Househo in China: discovery from 1995~2016 national fixed point survey data[J]. Management World, 2019, 35(10): 120-132. | |

| 2 | 张维理, 徐爱国, 冀宏杰, 等. 中国农业面源污染形势估计及控制对策Ⅲ.中国农业面源污染控制中存在问题分析[J]. 中国农业科学, 2004(7): 1026-1033. |

| Zhang Wei-li, Xu Ai-guo, Ji Hong-jie, et al. Estimation of agricultural non-point source pollution in china and the alleviating strategies Ⅲ. a review of policies and practices for agricultural non-point source pollution control in China[J]. Scientia Agricultura Sinica, 2004(7): 1026-1033. | |

| 3 | 马常宝. 我国农业肥料施用发展趋势与展望[J]. 中国农技推广, 2016, 32(6): 6-10. |

| Ma Chang-bao. Development trends and prospects of agriculture fertilizer application in China[J]. China Agricultural Extension, 2016, 32(6):6-10. | |

| 4 | 付宇超, 袁文胜, 张文毅, 等. 我国施肥机械化技术现状及问题分析[J]. 农机化研究, 2017, 39(1): 251-255, 263. |

| Fu Yu-chao, Yuan Wen-sheng, Zhang Wen-yi, et al. The research and development of the falling tree fruits and nuts collect and pick-up technology[I]. Journal of Agricultural Mechanization Research, 2017, 39(1): 251-255, 263. | |

| 5 | 施印炎, 陈满, 汪小旵, 等. 稻麦精准变量施肥机排肥性能分析与试验[J]. 农业机械学报, 2017, 48(7): 97-103. |

| Shi Yin-yan, Chen Man, Wang Xiao-chan, et al. Analysis and experiment of fertilizing performance for precision fertilizer applicator in rice and wheat fields[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 97-103. | |

| 6 | Anton F, Hubert Z, Georg B. Mass flowmeter for screw conveyors based on capactitive secsing[C]∥IEEE Instrumentation & Measurement Technology Conference, Warsaw, Poland, 2007. |

| 7 | 罗锡文, 廖娟, 胡炼, 等. 提高农业机械化水平促进农业可持续发展[J]. 农业工程学报, 2016, 32(1): 1-11. |

| Luo Xi-wen, Liao Juan, Hu Lian, et al. Improving agricultural mechanization level to promote agricultural sustainable development[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(1): 1-11. | |

| 8 | 兰志龙, Muhammad N K, Tanveer A S, 等. 25年长期定位不同施肥措施对关中塿土水力学性质的影响[J]. 农业工程学报, 2018, 34(24): 100-106. |

| Lan Zhi-long, Muhammad N K, Tanveer A S, et al. Effects of 25-year located different fertilization measures on soil hydraulic properties of lou soil in Guanzhong area[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(24): 100-106. | |

| 9 | 余洪锋, 丁永前, 刘海涛, 等. 小田块变量施肥系统优化设计与应用[J]. 农业工程学报, 2018, 34(3):35-41. |

| Yu Hong-feng, Ding Yong-qian, Liu Hai-tao, et al. Optimization design and application of variable rate fertilization system for small-scaled fields[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(3): 35-41. | |

| 10 | 郝友莉, 唐正宁, 季婷婷. 粉体包装机密实输送螺杆的设计[J]. 轻工机械, 2017, 35(5): 12-15. |

| Hao You-li, Tang Zheng-ning, Ji Ting-ting. Design of compact conveying screw for powder packaging machine[J]. Light Industry Machinery, 2017, 35(5): 12-15. | |

| 11 | 都红云, 赵军. 圆管螺旋给料机的设计与制作[J]. 现代面粉工业, 2014, 28(2): 16-19. |

| Du Hong-yun, Zhao Jun. Design and fabrication of round tube screw feeder[J]. Modern Flour Industry, 2014, 28(2): 16-19. | |

| 12 | 陈汝超,陈小平,蔡佳莹,等. 粒煤螺旋输送特性试验研究[J]. 煤炭学报,2012,37(1):154-157. |

| Chen Ru-chao, Chen Xiao-ping, Cai Jia-ying, et al. Screw conveying characteristics of granular coal from screw conveyor[J]. Journal of China Coal Society, 2012, 37(1): 154-157. | |

| 13 | Moysey P A, Thompson M R. Modelling the solids inflow and solids conveying of single-screw extruders using the discrete element method[J]. Powder Technology, 2005, 153(2): 95-107. |

| 14 | 刘彪, 肖宏儒, 宋志禹, 等. 果园施肥机械现状及发展趋势[J]. 农机化研究, 2017, 39(11): 263-268. |

| Liu Biao, Xiao Hong-ru, Song Zhi-yu, et al. Present state and trends of fertilizing machine in orchard[J]. Journal of Agricultural Mechanization Research, 2017, 39(11): 263-268. | |

| 15 | 王强. 2CMG-4型马铃薯播种机排肥系统的设计研究[D]. 呼和浩特: 内蒙古农业大学机电工程学院, 2014. |

| Qiang Wng. Design and research on the 2CMG-4 potato planter distributing system[D]. Hohhot: College of Mechanical and Electrial Engineering, Inner Mongolia Agricultural University, 2014. | |

| 16 | 薛忠, 赵亮, 王凤花, 等. 基于离散元法的螺旋式排肥器性能模拟试验[J]. 湖南农业大学学报: 自然科学版, 2019, 45(5): 548-553. |

| Xue Zhong, Zhao Liang, Wang Feng-hua, et al. Performance simulation test of the spiral fertilizer distributor based on discrete element method[J]. Journal of Hunan Agricultural University(Natural Sciences),2019, 45(5): 548-553. | |

| 17 | Kretz D, Callau-Monje S, Hitschler M, et al. Discrete element method (DEM) simulation and validation of ascrew feeder system[J]. Powder Technology, 2015, 287: 131-138. |

| 18 | Dheeraj M, Abhishek S, Harsh P, et al. A review of granular flow in screw feeders and conveyors[J]. Powder Technology, 2020, 366: 369-381. |

| 19 | 张涛, 刘飞, 刘月琴, 等. 离散元模拟外槽轮排肥器排量分析[J]. 农机化研究, 2015, 37(9): 198-201. |

| Zhang Tao, Liu Fei, Liu Yue-qin, et al. Discrete element simulation of outer groove wheel type fertilizer discharging device capacity analysis[J].Journal of Agricultural Mechanization Research, 2015, 37(9): 198-201. | |

| 20 | 顿国强,于春玲,郭艳玲,等. 双齿轮式排肥器设计与试验[J]. 农业机械学报,2020,51(3):87-96. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Design and experiment of double-gear type fertilizer apparatus[J]. Transactions of the Chinese Society for Agricultural Machinery,2020,51(3):87-96. | |

| 21 | 杨文武, 方龙羽, 罗锡文, 等. 螺旋排肥器排肥口参数对排肥性能影响的试验研究[J]. 农业工程学报, 2020, 36(17): 1-8. |

| Yang Wen-wu, Fang Long-yu, Luo Xi-wen, et al. Experimental study on the effect of the parameters of the spiral fertilizer feeder on the performance of the fertilizer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(17): 1-8. | |

| 22 | 胡勇克, 戴莉莉, 皮亚南. 螺旋输送器的原理与设计[J]. 南昌大学学报: 工科版, 2000(4): 29-33, 91. |

| Hu Ke-yong, Dai Li-li, Pi Ya-nan. Theories and calculation of the auger-type conveyer[J]. Journal of Nanchang University(Engineering & Technology), 2000(4): 29-33, 91. | |

| 23 | 中华人民共和国国家质量监督检验检疫总局. 变量施肥播种机控制系统: GB/T35487-2017[M]. 北京: 中国标准出版社, 2017. |

| 24 | 袁全春, 徐丽明, 邢洁洁, 等. 机施有机肥散体颗粒离散元模型参数标定[J]. 农业工程学报, 2018, 34(18): 21-27. |

| Yuan Quan-chun, Xu Li-ming, Xing Jie-jie, et al. Parameter calibration of discrete element model of organic fertilizer particles for mechanical fertilization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 21-27. | |

| 25 | 李晓贤, 赵进, 任震宇, 等. 小型竖直螺旋式精量条施机的设计[J]. 农机化研究, 2018, 40(12): 75-79. |

| Li Xiao-xian, Zhao Jin, Ren Zhen-yu, et al. The design of small vertical screw precision sliver[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2018, 40(12): 75-79. | |

| 26 | 陈雄飞, 罗锡文, 王在满, 等. 两级螺旋排肥装置的设计与试验[J]. 农业工程学报, 2015, 31(3): 10-16. |

| Chen Xiong-fei, Luo Xi-wen, Wang Zai-man,et al. Design and experiment of fertilizer distribution apparatus with double-level screws[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(3): 10-16. | |

| 27 | 吕金庆, 王泽明, 孙雪松, 等. 马铃薯螺旋推进式排肥器研究与试验[J]. 农机化研究, 2015, 37(6): 194-196, 200. |

| Jin-qing Lü, Wang Ze-ming, Sun Xue-song, et al. Design and experimental study of fFeed screw potato planter propulsion[J]. Journal of Agricultural Mechanization Research, 2015, 37(6): 194-196, 200. | |

| 28 | Yu Yao-wei, Henrik Saxe N. Experimental and DEM study of segregation of ternary size particles in a blast furnace top bunker model[J]. Chemical Engineering Science, 2010, 65: 5237-5250. |

| 29 | 杨洲, 朱卿创, 孙健峰, 等. 基于EDEM和3D打印成型的外槽轮排肥器排肥性能研究[J]. 农机化研究, 2018, 40(5): 175-180. |

| Yang Zhou, Zhu Qing-chuang, Sun Jian-feng, et al. Study on the performance of fluted roller fertilizer distributor based on EDEM and 3D printing[J]. Journal of Agricultural Mechanization Research, 2018, 40(5): 175-180. | |

| 30 | 徐中儒. 回归分析与试验设计[M]. 北京: 中国农业出版社, 1998. |

| 31 | 潘丽军. 试验设计与数据处理[M]. 南京: 东南大学出版社, 2008. |

| [1] | 史瑞杰,戴飞,赵武云,杨发荣,张锋伟,赵一鸣,曲浩,王天福,郭军海. 自走式藜麦联合收割机设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2686-2694. |

| [2] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [3] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [4] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [5] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [6] | 耿端阳,纪晓琦,牟孝栋,李华彪,杨昊霖,姚艳春,武继达. 构树收获割台设计与试验[J]. 吉林大学学报(工学版), 2023, 53(7): 2152-2164. |

| [7] | 曹肆林,谢建华,杨豫新,刘永瑞,卢勇涛,孙博. 侧排式棉秸秆还田及残地膜回收联合作业机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(5): 1514-1528. |

| [8] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [9] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [10] | 张学军,黄爽,史增录,于永良,周鑫城,靳伟,陈勇,洪佳. 残膜捡拾打包机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1220-1230. |

| [11] | 陈永,陈学庚,何浩猛,罗昕,余幸,胡斌. 基于灌溉引水渠介质的膜秆分离装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1245-1256. |

| [12] | 荣鑫,刘洪海,殷作耀,林海翔,边庆华. 基于图像处理的集料级配在线检测方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2847-2855. |

| [13] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [14] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [15] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

|

||