吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (11): 2746-2755.doi: 10.13229/j.cnki.jdxbgxb20210377

• 农业工程·仿生工程 • 上一篇

丘陵山地胡麻联合收割机作业参数优化与试验

史瑞杰1( ),戴飞1,赵武云1(

),戴飞1,赵武云1( ),刘小龙1,瞿江飞2,张锋伟1

),刘小龙1,瞿江飞2,张锋伟1

- 1.甘肃农业大学 机电工程学院,兰州 730070

2.兰州信息科技学院 教师与干部发展中心,兰州 730300

Optimization and experiment of operation parameters of hilly area flax combine harvester

Rui-jie SHI1( ),Fei DAI1,Wu-yun ZHAO1(

),Fei DAI1,Wu-yun ZHAO1( ),Xiao-long LIU1,Jiang-fei QU2,Feng-wei ZHANG1

),Xiao-long LIU1,Jiang-fei QU2,Feng-wei ZHANG1

- 1.College of Mechanical and Electrical Engineering,Gansu Agricultural University,Lanzhou 730070,China

2.Teacher and Cadre Development Center,Lanzhou College of Information Science and Technology,Lanzhou 730300,China

摘要:

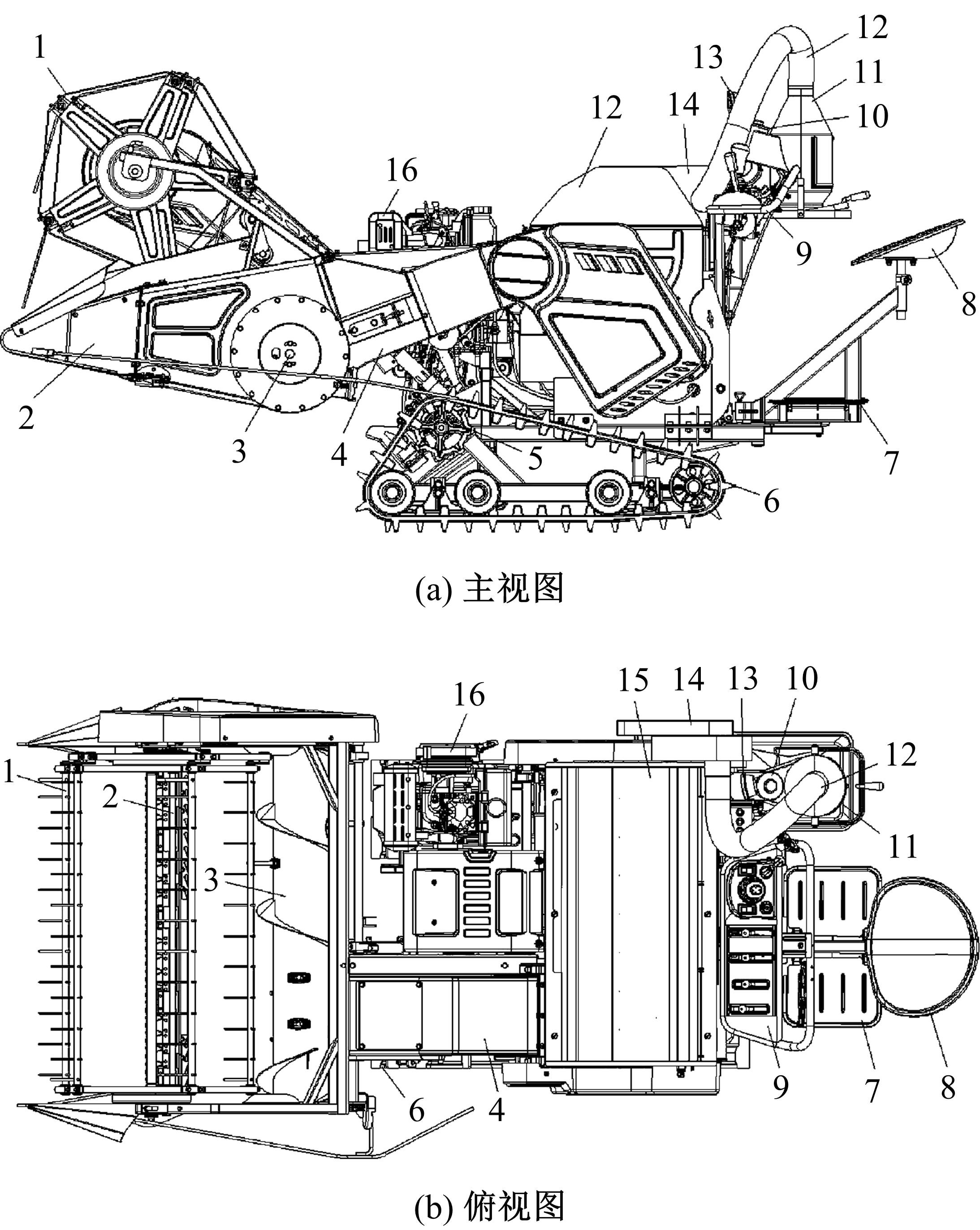

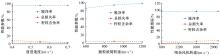

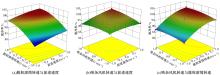

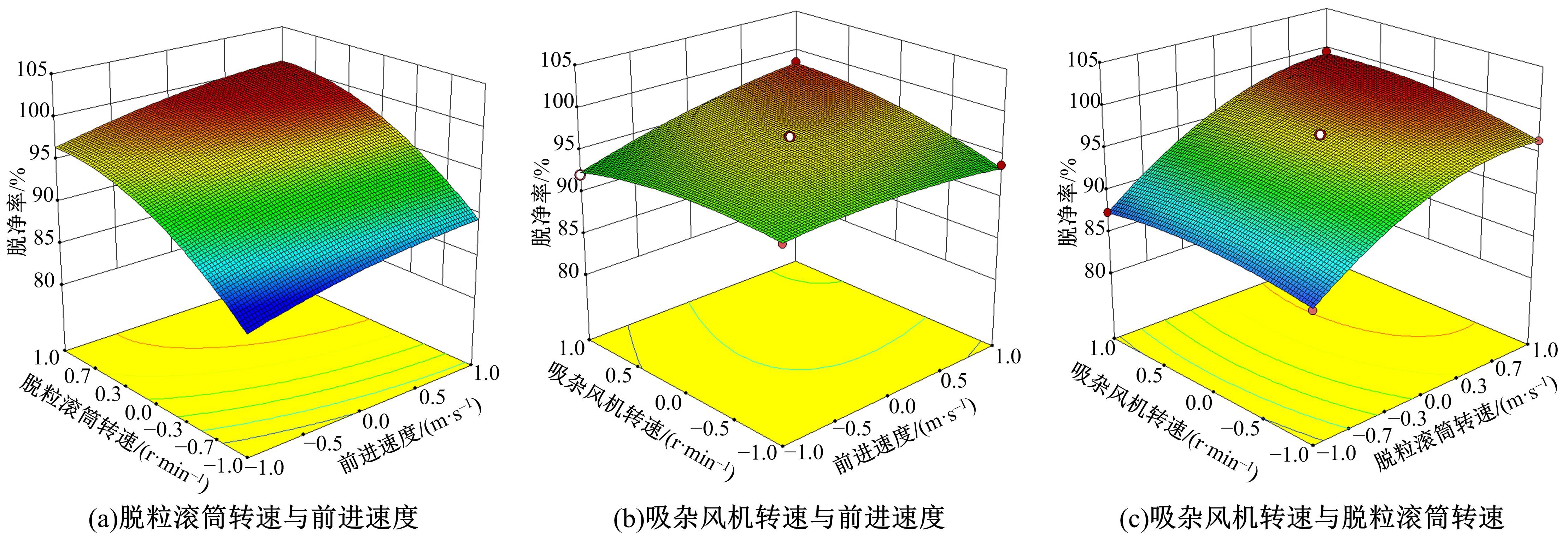

为提高丘陵山地胡麻联合收割机工作效率,该研究以作业机前进速度、脱粒滚筒转速和吸杂风机转速为自变量,以脱净率、总损失率和籽粒含杂率为响应值,依照Box-Behnken试验设计原理,采用三因素三水平响应面分析方法分别建立各因素与响应值间的数学模型,并对各因素及其交互作用进行分析。结果表明:3个因素对脱净率影响的主次顺序为脱粒滚筒转速、前进速度和吸杂风机转速,对总损失率影响的主次顺序为前进速度、吸杂风机转速和脱粒滚筒转速,对籽粒含杂率影响的主次顺序为吸杂风机转速、脱粒滚筒转速和前进速度;作业机最佳工作参数如下:前进速度为0.65 m/s、脱粒滚筒转速为830.3 r/min、吸杂风机转速为1154.39 r/min。在最优工作参数下作业机脱净率、总损失率和籽粒含杂率均值分别为96.33%、1.87%和3.24%,说明在该作业参数下作业机能够降低收获总损失和籽粒含杂率。

中图分类号:

- S225.31

| 1 | 祁旭升,王兴荣,许军,等.胡麻种质资源成株期抗旱性评价[J].中国农业科学, 2010, 43(15): 3076-3087. |

| Qi Xu-sheng, Wang Xing-rong, Xu Jun . et al. Drought-resistance evaluation of flax germplasm at adult plant stage[J]. Scientia Agricultura Sinica, 2010, 43(15): 3076-3087. | |

| 2 | 罗俊杰, 欧巧明, 叶春雷, 等. 重要胡麻栽培品种的抗旱性综合评价及指标筛选[J]. 作物学报, 2014, 40(7): 1259-1273. |

| Luo Jun-jie, Qiao-ming Ou, Ye Chun-lei, et al. Comprehensive valuation of drought resistance and screening of indices of important flax cultivars[J]. Acta Agronomica Sinica, 2014, 40(7): 1259-1273. | |

| 3 | 史瑞杰, 戴飞, 赵武云, 等. 全喂入式胡麻脱粒机的设计与试验[J]. 中国农业大学学报, 2019, 24(8): 120-132. |

| Shi Rui-jie, Dai Fei, Zhao Wu-yun, et al. Design and test of full-feed flax thresher[J]. Journal of China Agricultural University, 2019, 24(8): 120-132. | |

| 5 | 刘元祥, 戴飞, 赵武云, 等. 手扶式胡麻割晒机的设计与试验[J].中国农机化学报, 2019, 40(12): 26-29. |

| Liu Yuan-xiang, Dai Fei, Zhao Wu-yun, et al. Design and experiment of handheld flax windrower[J]. Journal of Chinese Agricultural Mechanization, 2019, 40(12): 26-29. | |

| 6 | 孙仕明, 孙文峰, 吕海杰. 我国亚麻生产机械化现状及发展建议[J]. 农机化研究, 2004(4): 23-24. |

| Sun Shi-ming, Sun Wen-feng, Lv Hai-jie. The present status and development suggestion on flax production mechanization in our country[J]. Journal of Agricultural Mechanization Research,2004(4): 23-24. | |

| 7 | 屈哲, 余泳昌, 何勋. 我国西南丘陵地区玉米收获机械化的研究探讨[J]. 现代农业装备, 2013(3): 26-29. |

| Qu Zhe, Yu Yong-chang, He Xun. Research and discuss about corn harvest mechanization in southwest hilly area of our country[J]. Modern Agricultural Equipment, 2013(3): 26-29. | |

| 8 | 戴飞, 赵武云, 刘国春, 等. 胡麻脱粒物料分离清选机设计与试验[J]. 农业机械学报, 2019, 50(8): 140-147. |

| Dai Fei, Zhao Wu-yun, Liu Guo-chun, et al. Design and experiment of separating and cleaning machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 140-147. | |

| 9 | 戴飞, 赵武云, 宋学锋, 等. 胡麻脱粒物料分离清选作业机参数优化与试验[J]. 农业机械学报, 2020, 51(7): 100-108. |

| Dai Fei, Zhao Wu-yun, Song Xue-feng, et al. Parameters optimization and experiment on separating and cleaning materia machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(7): 100-108. | |

| 10 | 周刚, 石林榕, 赵武云, 等. 旱地胡麻起垄覆膜播种联合作业机工作参数优化与性能试验[J]. 中国农业大学学报, 2019, 24(6): 147-156. |

| Zhou Gang, Shi Lin-rong, Zhao Wu-yun, et al. Optimization of the working parameters and performance experiment of flax ridging and covering film combined seeder in dry-land[J]. Journal of China Agricultural University, 2019, 24(6): 147-156. | |

| 11 | 石林榕, 马周泰, 赵武云, 等. 胡麻籽粒离散元仿真参数标定与排种试验验证[J]. 农业工程学报, 2019, 35(20): 25-33. |

| Shi Lin-rong, Ma Zhou-tai, Zhao Wu-yun, et al. Calibration of simulation parameters of flaxed seeds using discrete element method and verification of seed-metering test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(20): 25-33. | |

| 12 | 史瑞杰, 戴飞, 刘小龙, 等. 履带式丘陵山地胡麻联合收割机设计与试验[J]. 农业工程学报, 2021, 37(5): 59-67. |

| Shi Rui-jie, Dai Fei, Liu Xiao-long, et al. Design and experiments of crawler-type hilly area flax combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(5): 59-67. | |

| 13 | 史瑞杰, 戴飞, 赵武云, 等. 胡麻茎秆生物力学特性试验[J]. 中国农机化学报, 2018, 39(11): 45-50. |

| Shi Rui-jie, Dai Fei, Zhao Wu-yun, et al. Biomechanical properties test of flax stem[J]. Journal of Chinese Agricultural Mechanization,2018,39(11): 45-50. | |

| 14 | .收获机械 联合收割机 试验方法 [S]. |

| 15 | .脱粒机试验方法 [S]. |

| 16 | .计数抽样检测程序 [S]. |

| 17 | .农业机械试验条件 [S]. |

| 18 | .谷物联合收割机 安全操作规程 [S]. |

| 19 | Shamilah A M, Darius E P, Nor A A J. Actual field speed of rice combine harvester and its influence on grain loss in Malaysian paddy field[J]. Journal of the Saudi Society of Agricultural Sciences, 2020, 19(6): 422-425. |

| 20 | Chai X Y, Zhou Y, Xu L Z, et al. Effect of guide strips on the distribution of threshed outputs and cleaning losses for a tangential-longitudinal flow rice combine harvester[J]. Biosystems Engineering, 2020, 198: 223-234. |

| 21 | 中国农业机械化科学研究院. 农业机械设计手册: 上册[M]. 北京: 中国农业科学技术出版社, 2007. |

| 22 | 戴飞, 赵武云, 马明义, 等. 双垄耕作施肥喷药覆膜机工作参数优化[J]. 农业机械学报, 2016, 47(1):83-90. |

| Dai Fei, Zhao Wu-yun, Ma Ming-yi,et al. Parameters optimization of operation machine for tillage-fertilization and spraying filming on double ridges[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 83-90. | |

| 23 | 张仕林, 赵武云, 戴飞, 等. 全膜双垄沟起垄覆膜机镇压作业过程仿真分析与试验[J]. 农业工程学报, 2020, 36(1): 20-30. |

| Zhang Shi-lin, Zhao Wu-yun, Dai Fei, et al. Simulation analysis and test on suppression operation process of ridging and film covering machine with full-film double-furrow[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(1):20-30. | |

| 24 | 金诚谦, 郭飞扬, 徐金山, 等. 大豆联合收获机作业参数优化[J]. 农业工程学报, 2019, 35(13): 10-22. |

| Jin Cheng-qian, Guo Fei-yang, Xu Jin-shan, et al. Optimization of working parameters of soybean combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(13): 10-22. | |

| 25 | 王伯凯, 胡志超, 曹明珠, 等. 轴流式花生捡拾收获机设计与试验[J]. 农业机械学报, 2021, 52(1): 98, 109-118. |

| Wang Bo-kai, Hu Zhi-chao, Cao Ming-zhu, et al. Design and Test of axial-flow peanut picking and harvesting machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(1): 98, 109-118. | |

| 26 | 黄继承, 沈成, 纪爱敏, 等. 工业大麻收割机切割-输送关键部件作业参数优化[J]. 吉林大学学报: 工学版, 2021, 51(2): 772-780. |

| Huang Ji-cheng, Shen Cheng, Ji Ai-min, et al. Optimization of cutting-conveying key working parameters of hemp harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2):772-780. | |

| 27 | 薛钊, 付君, 陈志, 等. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报: 工学版, 2020, 50(2): 739-748. |

| Xue Zhao, Fu Jun, Chen Zhi, et al. Optimization experiment on parameters of chopping device of forage maize harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2):739-748. |

| [1] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [2] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [3] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

| [4] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [5] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [6] | 耿端阳,牟孝栋,张国栋,王宗源,朱俊科,徐海刚. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报(工学版), 2022, 52(1): 219-230. |

| [7] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [8] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [9] | 张斌,程国赞,洪昊岑,赵春晓,白大鹏,杨华勇. 基于SVR的轴向柱塞泵配流盘三角槽结构优化[J]. 吉林大学学报(工学版), 2021, 51(4): 1213-1221. |

| [10] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [11] | 黄继承,沈成,纪爱敏,李显旺,张彬,田昆鹏,刘浩鲁. 工业大麻收割机切割⁃输送关键部件作业参数优化[J]. 吉林大学学报(工学版), 2021, 51(2): 772-780. |

| [12] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [13] | 陈学深,陈涛,武涛,马旭,曾令超,陈林涛. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报(工学版), 2020, 50(2): 749-757. |

| [14] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [15] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

|

||