吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (11): 3045-3055.doi: 10.13229/j.cnki.jdxbgxb.20211131

• 车辆工程·机械工程 • 下一篇

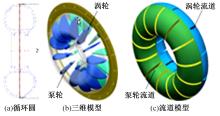

制动工况桃腔偶合器三维涡特征分析及仿真评价

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.吉林大学 汽车底盘集成与仿生全国重点实验室,长春 130022

3.中机试验装备股份有限公司,长春 130103

Three-dimensional vortex characteristic analysis and simulation evaluation of peach cavity hydrodynamic coupling under braking condition

Bo-sen CHAI1,2,3( ),Dong YAN1,Guang-yi WANG1,Wen-jie ZUO1,2

),Dong YAN1,Guang-yi WANG1,Wen-jie ZUO1,2

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.National Key Laboratory of Automotive Chassis Integration and Bionics,Jilin University,Changchun 130022,China

3.Sinotest Equipment Co. ,Ltd. ,Changchun 130103,China

摘要:

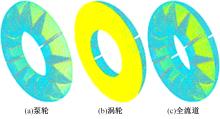

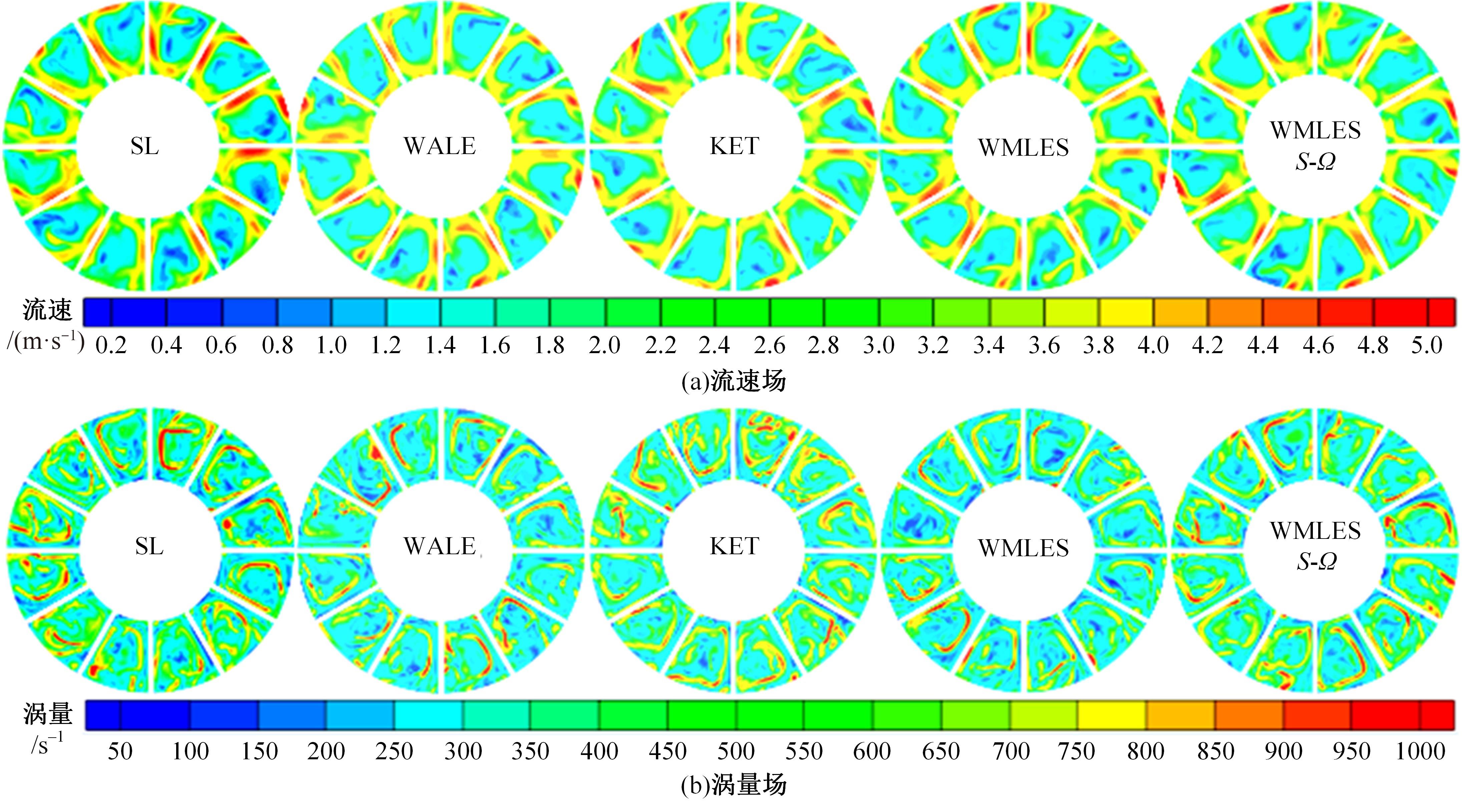

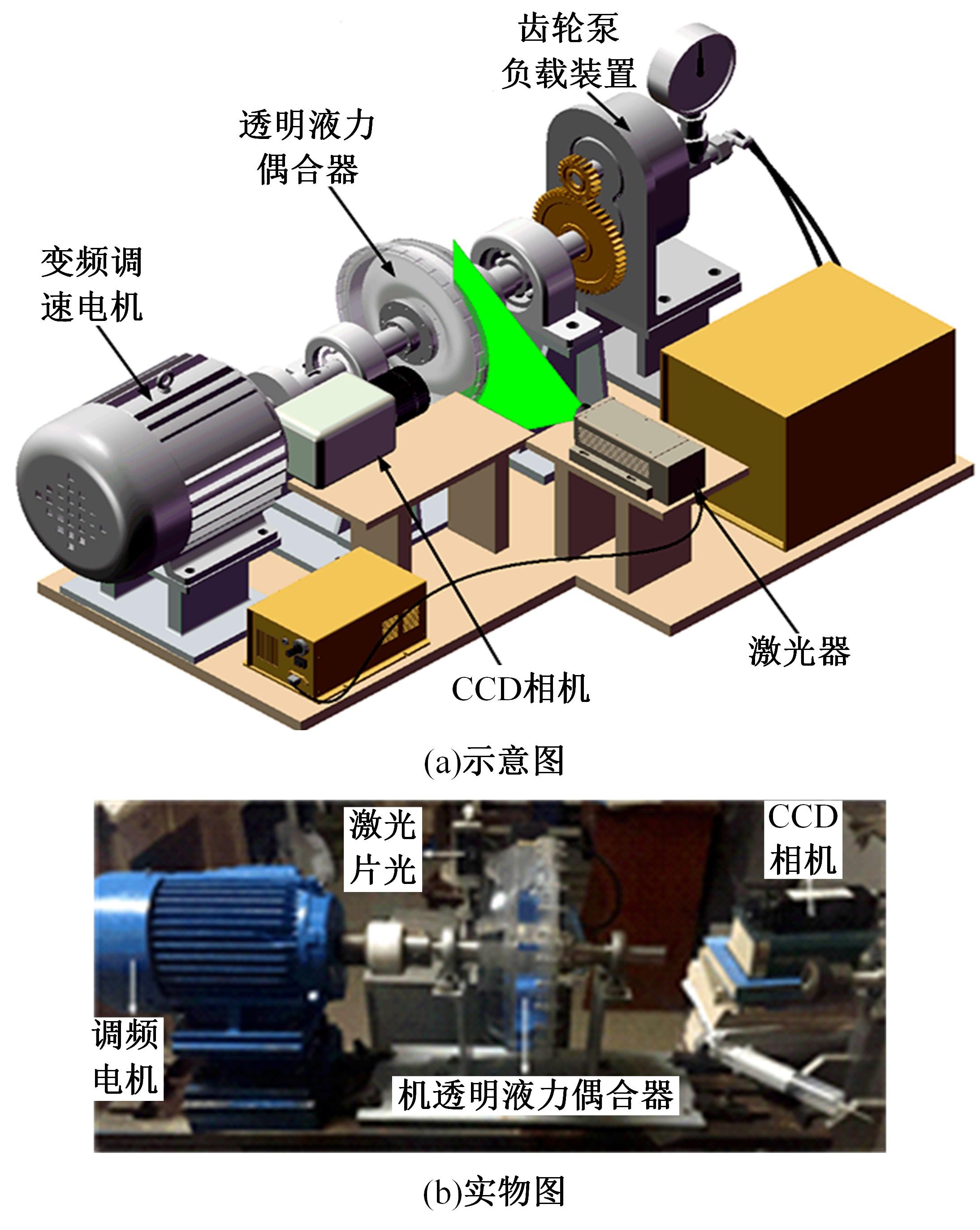

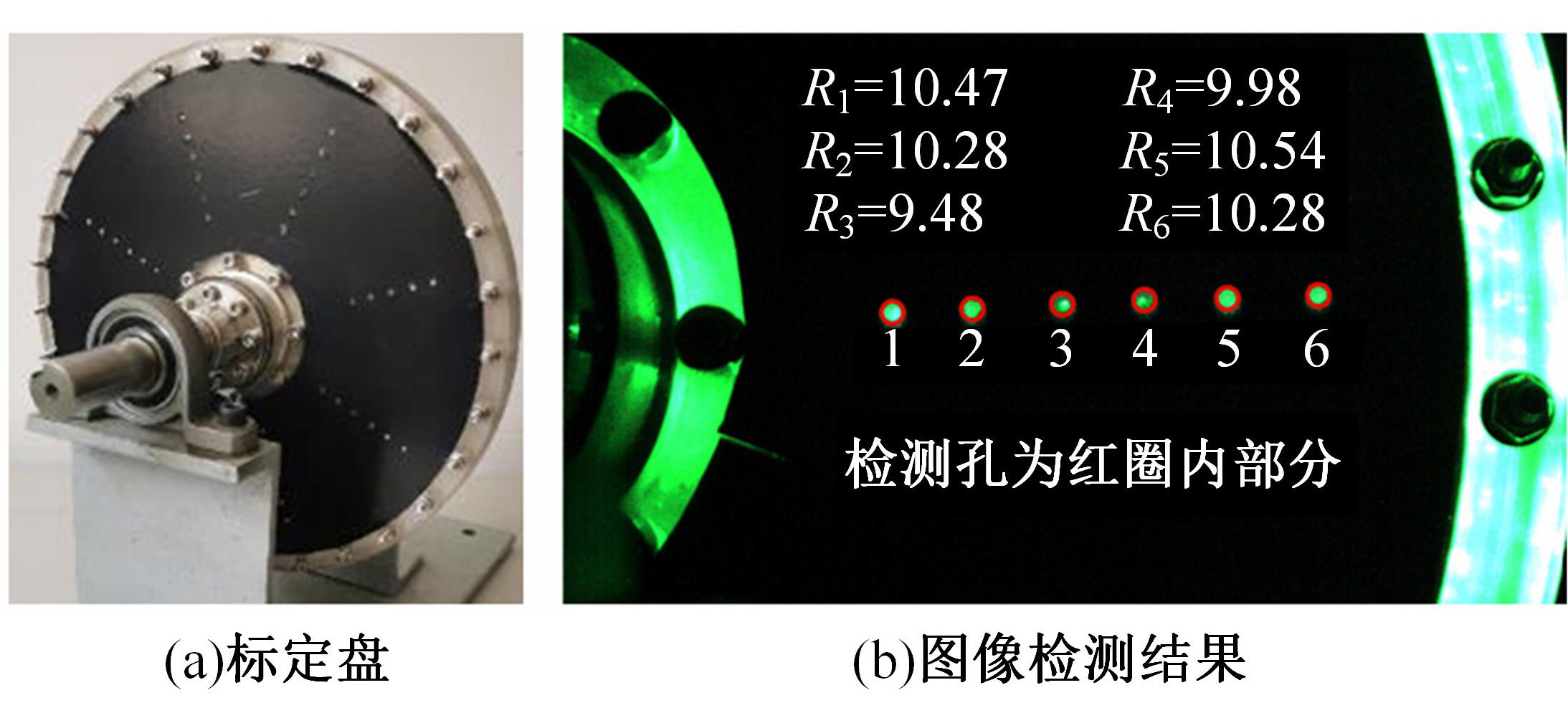

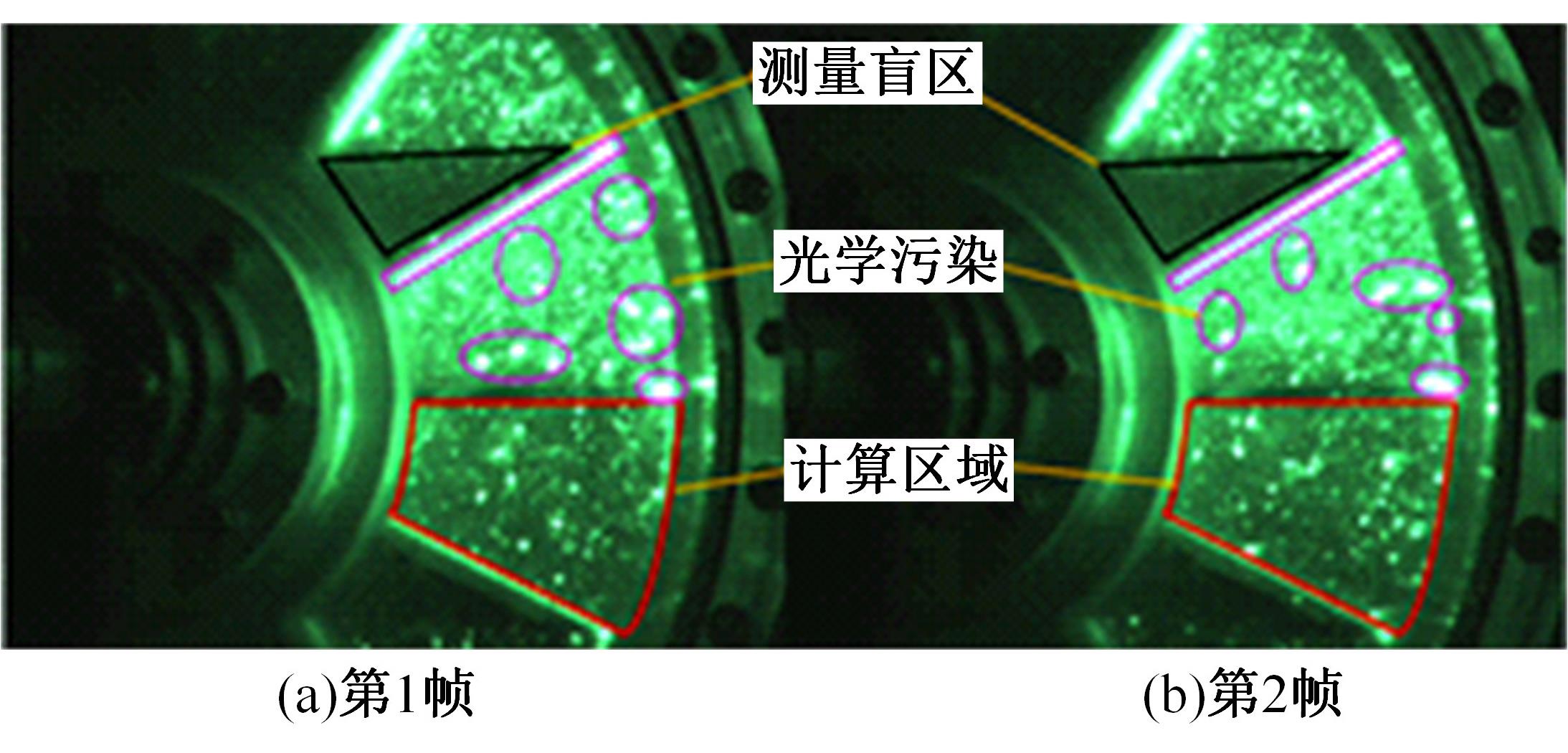

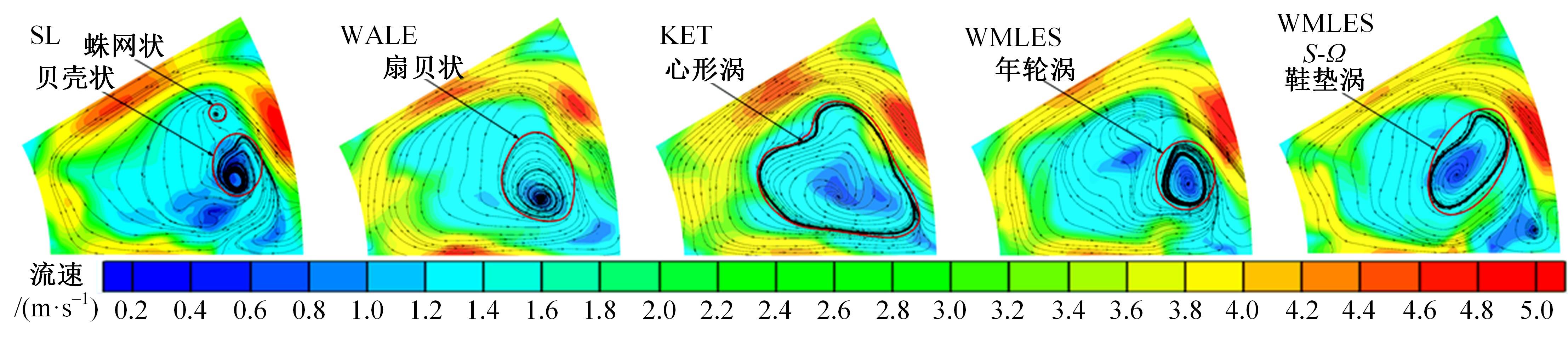

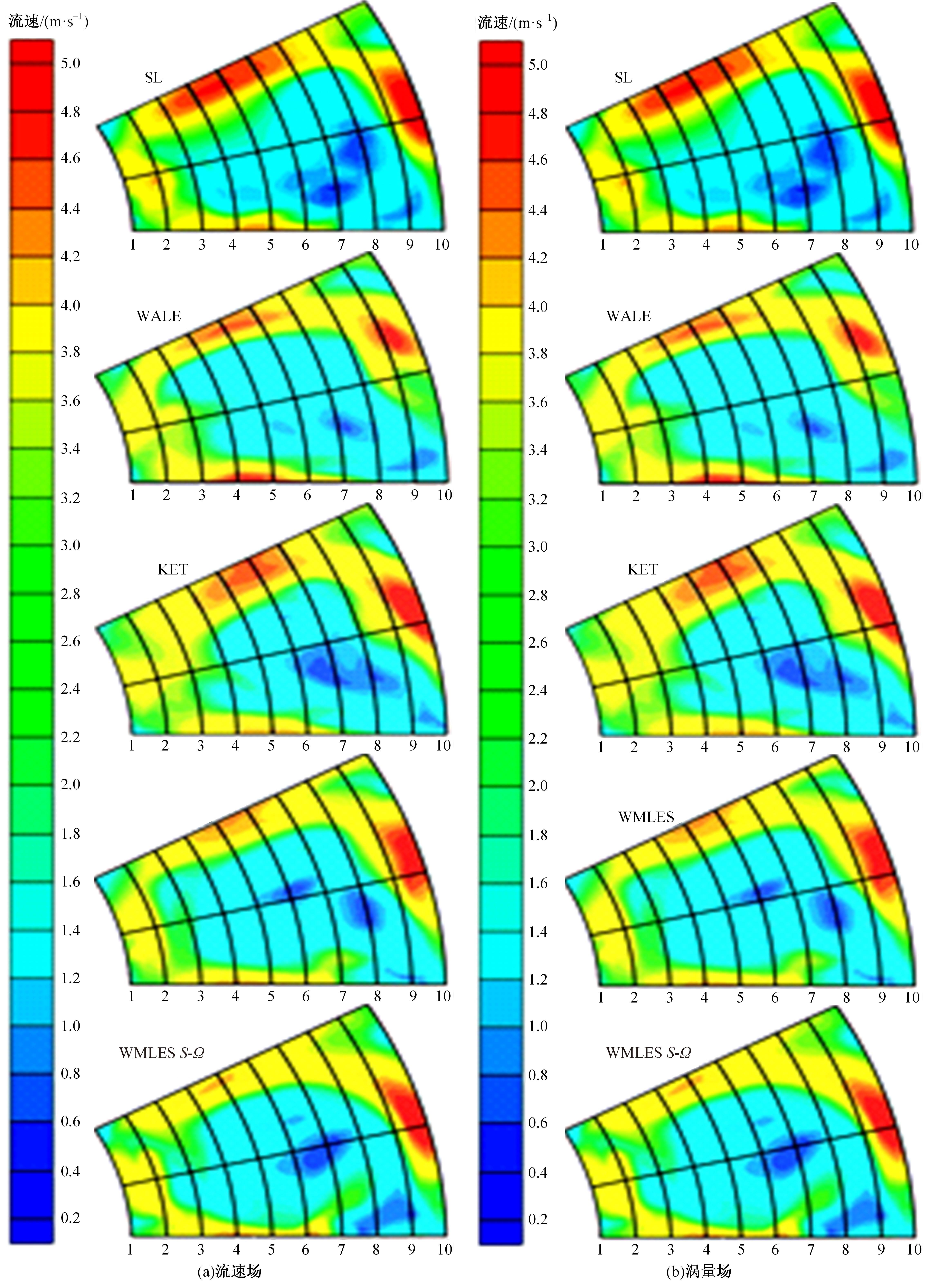

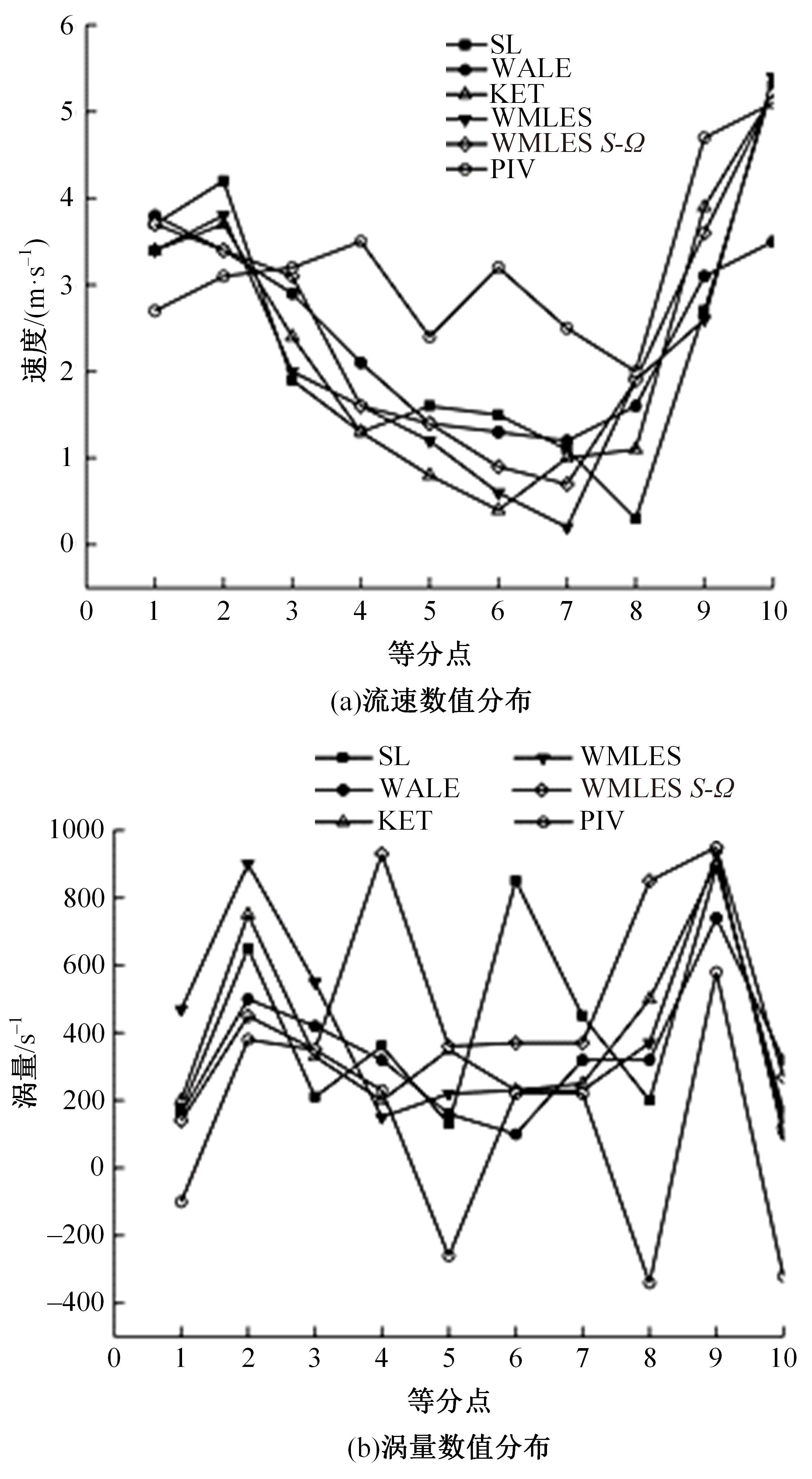

基于大涡模拟采用不同亚格子湍流模型仿真桃腔液力偶合器制动工况下流场,采用Q准则涡识别方法提取涡轮三维多尺度涡结构特征。通过粒子图像测速流场可视化试验验证及评价仿真结果的准确性和可靠性。从三维涡与二维流场提取两方面综合来看:WMLES S-Ω模型对叶片近壁面三维多尺度涡仿真信息丰富,小尺度涡捕获准确;WALE模型对叶片与外环交汇角隅区小尺度涡识别准确;WMLES S-Ω模型对主流区二维流场仿真结果真实,能呈现角隅区二次流现象;WMLES模型对叶片近壁面二维流场仿真数值分布与试验值吻合。研究结果可为液力偶合器流场仿真提供一定的理论与技术指导。

中图分类号:

- TH137.331

| 1 | 初长祥, 马文星. 工程机械液压与液力传动系统(液力卷)[M]. 北京: 化学工业出版社, 2015. |

| 2 | 魏巍, 闫清东. 液力元件设计[M]. 北京: 北京理工大学出版社, 2015. |

| 3 | 郭昀朋. 液力耦合器电动给水泵变频改造技术应用研究[D]. 广州: 华南理工大学机械与汽车工程学院, 2018. |

| Guo Yun-peng. Research on frequency conversion technology of electric feed pump by hydraulic coupling[D]. Guangzhou: School of Mechanical and Automotive Engineering, South China University of Technology, 2018. | |

| 4 | Hur N, Kwak M, Moshfeghi M, et al. Numerical flow analyses of a two-phase hydraulic coupling[J]. Journal of Mechanical Science and Technology, 2017, 31(5): 2307-2317. |

| 5 | Silva M J D, Lu Y, Sühnel T, et al. Autonomous planar conductivity array sensor for fast liquid distribution imaging in a fluid coupling[J]. Sensors and Actuators A: Physical, 2008, 147(2): 508-515. |

| 6 | Hampel U, Hoppe D, Diele K H, et al. Application of gamma tomography to the measurement of fluid distributions in a hydrodynamic coupling[J]. Flow Measurement and Instrumentation, 2005, 16(2/3): 85-90. |

| 7 | Khatir T, Bouchetara M, Boutchicha D. Dynamics study of the operating behavior of hydrodynamic coupling by experimental and numerical simulation[J]. Mechanika, 2014, 20(4): 395-401. |

| 8 | 卢秀泉, 马霖, 马文星, 等. 导轮关键参数对液力变矩偶合器性能的影响[J]. 吉林大学学报: 工学版, 2019, 49(2): 444-450. |

| Lu Xiu-quan, Ma Lin, Ma Wen-xing, et al. Effects of key parameters of stator on the performance of hydrodynamic coupling torque converter[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(2): 444-450. | |

| 9 | 魏巍, 李双双, 安媛媛,等. 液力缓速器低充液率工况扰流柱起效条件判定方法[J]. 北京理工大学学报, 2017, 37(7): 672-676. |

| Wei Wei, Li Shuang-shuang, An Yuan-yuan, et al. Determing method for spoilers operating condition at low oil charging ratio in hydrodynamic retarder[J]. Transactions of Beijing Institute of Technology, 2017, 37(7), 672-676. | |

| 10 | 李晋, 闫清东, 王玉岭, 等. 液力变矩器泵轮内流场非定常流动现象研究[J]. 机械工程学报, 2016, 52(14): 188-195. |

| Li Jin, Yan Qing-dong, Wang Yu-ling, et al. Research on unsteady flow field of the pump in hydraulic torque converter[J]. Journal of Mechanical Engineering, 2016, 52(14), 188-195. | |

| 11 | 张嘉华, 崔红伟, 常宗旭,等. 基于CFD技术的调速型液力偶合器两相流分析方法研究[J]. 液压与气动, 2020(6): 90-96. |

| Zhang Jia-hua, Cui Hong-wei, Chang Zong-xu, et al. Two-phase flow analysis method of variable speed hydraulic coupling based on CFD techonology[J]. Chinese Hydraulics & Pneumatics, 2020(6): 90-96. | |

| 12 | 柴博森, 项玥, 马文星, 等. 制动工况下液力偶合器流场湍流模型分析与验证[J]. 农业工程学报, 2016, 32(3): 34-40. |

| Chai Bo-sen, Xiang Yue, Ma Wen-xing, et al. Analysis and experimental verification of turbulence models in flow simulation for hydrodynamic coupling under braking condition[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(3): 34-40. | |

| 13 | Goyal R, Gandhi B K, Cervantes M J. PIV measurements in francis turbine—a review and application to transient operations[J]. Renewable & Sustainable Energy Reviews, 2018, 81(2): 2976-2991. |

| 14 | Atkinson C, Buchner A J, Eisfelder M, et al. Time-resolved PIV measurements of a self-similar adverse pressure gradient turbulent boundary layer[J]. Mechanical & Aerospace Engineering, 2016(6): 54014301. |

| 15 | González-Neria I, Alonzo-Garcia A, Martínez-Delgadillo S A, et al. PIV and dynamic LES of the turbulent stream and mixing induced by a V-grooved blade axial agitator[J]. Chemical Engineering Journal, 2019, 374: 1138-1152. |

| 16 | 李勇. 基于深度学习的粒子图像测速算法研究及应用[D]. 武汉: 华中科技大学机械科学与工程学院. 2018. |

| Li Yong. Deep learning based particle image velocimetry technology and its application[D]. Wuhan: School of Machanical Science and Engineering, Huazhong University of Science and Technology, 2018. | |

| 17 | 柴博森, 项玥, 刘勇, 等. 基于PIV试验的水介质液力偶合器涡轮流场仿真评价[J]. 华南理工大学学报:自然科学版, 2018, 46(5): 125-134. |

| Chai Bo-sen, Xiang Yue, Liu Yong, et al. Evaluation of flow field simulation of turbine in water-medium hydrodynamic coupling based on PIV experiment[J]. Journal of South China University of Technology(Natural Science Edition), 2018, 46(5): 125-134. | |

| 18 | 柴博森, 项玥, 马文星, 等. 制动工况下液力偶合器涡轮轴向漩涡流场试验分析[J]. 农业工程学报, 2017, 33(8): 69-75. |

| Chai Bo-sen, Xiang Yue, Ma Wen-xing, et al. Experimental analysis on axial vortex flow field of turbine in hydrodynamic coupler under braking condition[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(8): 69-75. | |

| 19 | 卢秀泉,胡春玉,柴亚龙,等. 大功率液力偶合器调速工况瞬态流场特性[J]. 吉林大学学报:工学版, 2019, 49(5): 1539-1546. |

| Lu Xiu-quan, Hu Chun-yu, Chai Ya-long, et al. Analysis of transient flow field characteristics of large-scale hydrodynamic coupling under speed regulation[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1539-1546. | |

| 20 | Nikiforova K V, Guseva E K, Garbaruk A V. Application of WMLES to wall-bounded flows with pressure gradient[J]. Journal of Physics: Conference Series, 2018, 1135(1): 12-98. |

| 21 | 柴博森, 王玉建, 刘春宝, 等. 基于粒子图像测速技术的液力变矩器涡轮内流场测试与分析[J]. 农业工程学报, 2015, 31(12): 96-98. |

| Chai Bo-sen, Wang Yu-jian, Liu Chun-bao, et al. Test and analysis of internal flow field in turbine of hydrodynamic torque converter based on particle image velocimetry[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(12): 96-98. |

| [1] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [2] | 柴博森,王广义,闫东,朱国仁,张进,吕恒升. 液力变矩器空化数值模拟及对性能的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2236-2244. |

| [3] | 陈国辉,徐业银,焦映厚. 考虑偏转的斜齿轮啮合刚度及其振动分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1902-1910. |

| [4] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [5] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

| [6] | 李胜,朱佳,黄德惠,陈存福,费洪庆,丰伟,胡兴军. 空冷中冷器百叶窗翅片结构参数优化[J]. 吉林大学学报(工学版), 2023, 53(4): 998-1006. |

| [7] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

| [8] | 朱凌,王秋成. 空间几何约束下新能源汽车驱动系统协调控制方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1509-1514. |

| [9] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

| [10] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [11] | 李国发,王彦博,何佳龙,王继利. 机电装备健康状态评估研究进展及发展趋势[J]. 吉林大学学报(工学版), 2022, 52(2): 267-279. |

| [12] | 王磊,黄秉汉,丛家慧,回丽,周松,徐永臻. 超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2542-2548. |

| [13] | 赵文伯,李玉洁,邓俊,李理光,吴志军. 针阀运动规律及其对喷嘴内流和喷雾特性影响[J]. 吉林大学学报(工学版), 2022, 52(10): 2234-2243. |

| [14] | 胡兴军,张靖龙,辛俐,罗雨霏,王靖宇,余天明. 冷却管结构及风速对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1557-1564. |

| [15] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

|