吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (1): 20-35.doi: 10.13229/j.cnki.jdxbgxb.20230841

沥青发泡特性及温拌混合料水分敏感性综述

- 1.重庆交通大学 土木工程学院,重庆 400074

2.广西道路结构与材料重点实验室,南宁 530007

3.重庆交通大学 交通土建工程材料国家地方联合工程实验室,重庆 400074

4.同济大学 道路与交通工程教育部重点实验室,上海 201804

Review of characteristics of asphalt foaming and moisture sensitivity of warm mix mixtures

Wan-feng WEI1,2( ),Ling-yun KONG3(

),Ling-yun KONG3( ),Wei-an XUAN2,Fan YANG4,Peng GUO3

),Wei-an XUAN2,Fan YANG4,Peng GUO3

- 1.School of Civil Engineering,Chongqing Jiaotong University,Chongqing 400074,China

2.Guangxi Key Laboratory of Road Structure and Materials,Nanning 530007,China

3.National and Local Joint Engineering Laboratory of Transportation Civil Engineering Materials,Chongqing Jiaotong University,Chongqing 400074,China

4.Key Laboratory of Road and Traffic Engineering of Ministry of Education,Tongji University,Shanghai 201804,China

摘要:

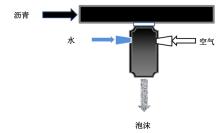

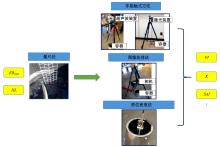

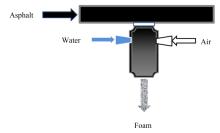

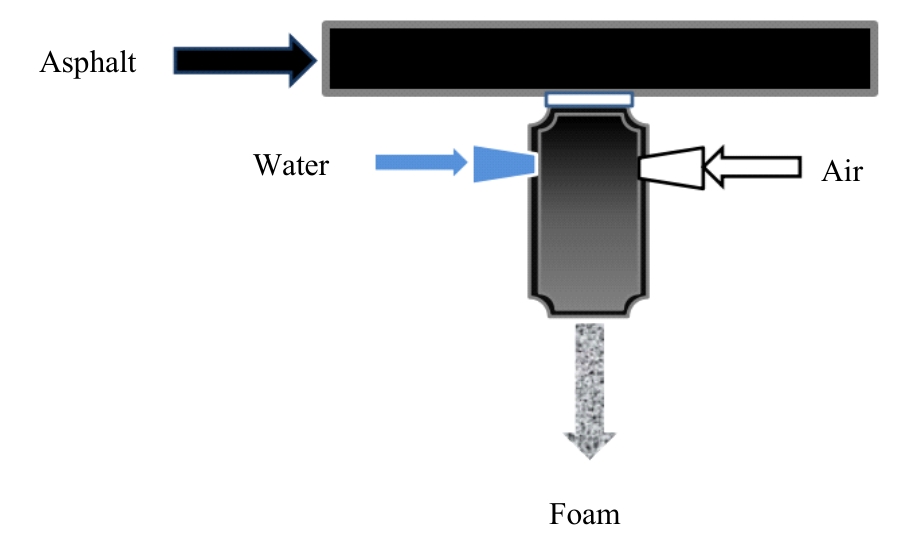

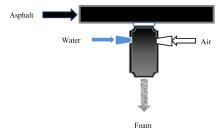

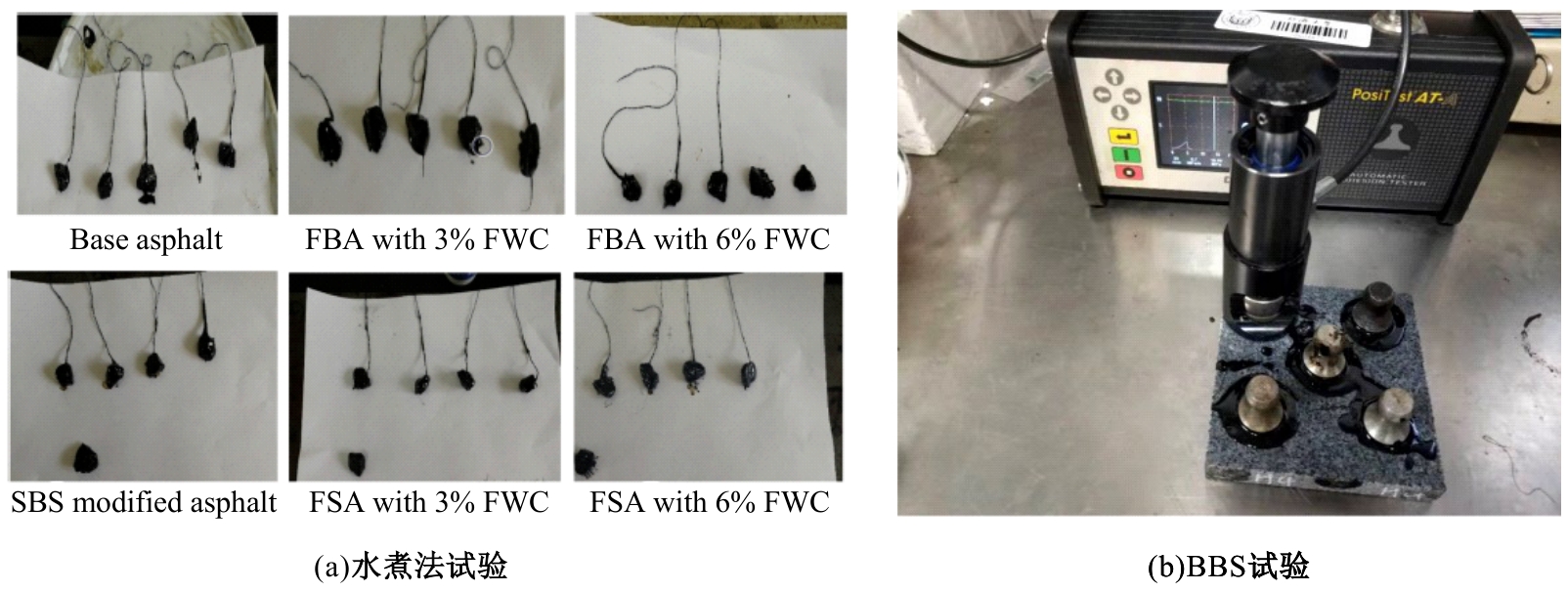

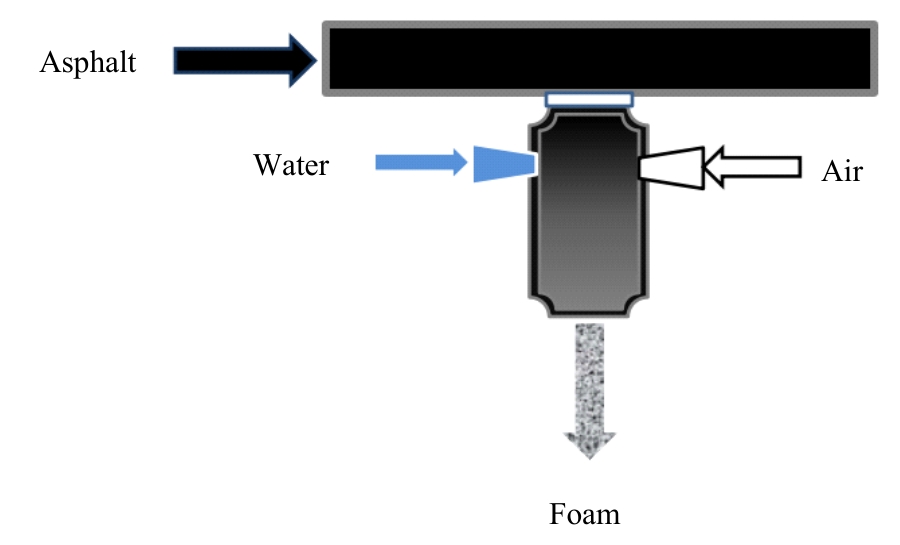

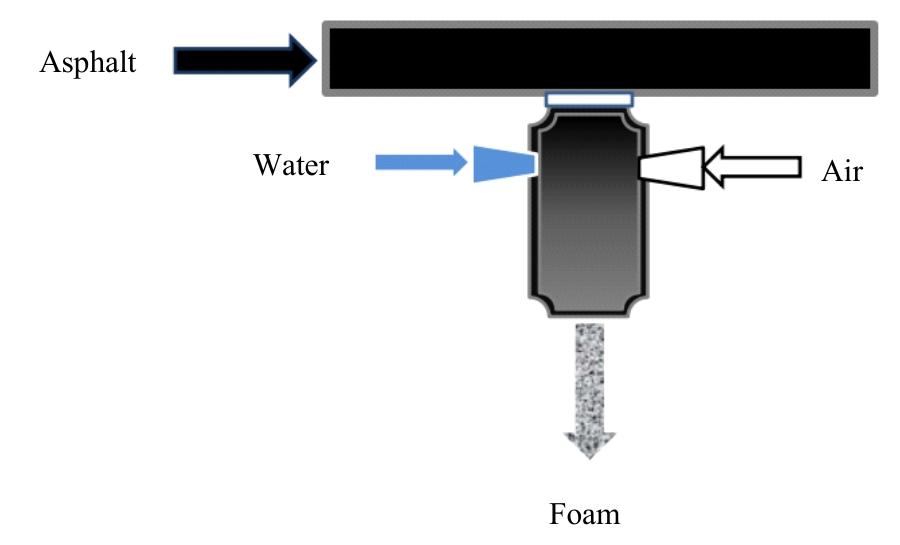

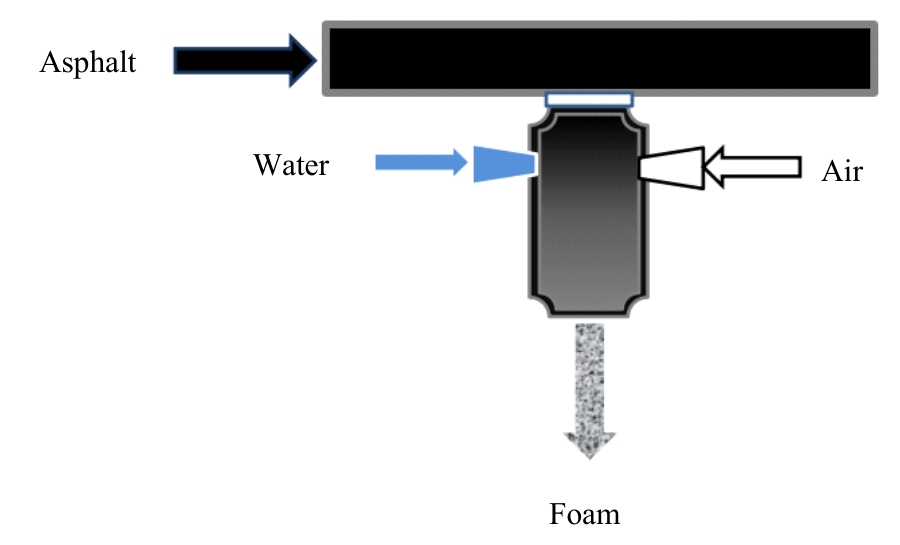

本文基于沥青发泡特性及泡沫温拌沥青混合料水分敏感性的相关研究,阐述了沥青发泡机理,分析了沥青发泡效果影响因素、沥青发泡效果评价指标及发泡过程对沥青性质的影响;针对泡沫温拌沥青混合料存在抗水损害能力偏低的现实情况,指出沥青经过发泡之后,会有部分水分及泡沫残留在沥青之中,从不同角度剖析了水分对泡沫温拌沥青混合料沥青-集料黏附性的影响,并对泡沫温拌沥青混合料现存问题的解决途径进行了分析、总结与展望。现阶段,ERmax(最大膨胀率)、HL(半衰期)等评价沥青发泡效果的指标存在一定的局限性,且沥青发泡状态与混合料性能的相关性未明确,可利用激光测距、动态X射线摄影、图像处理等手段研究沥青发泡的全过程,分析相关发泡参数对泡沫沥青胶结料及混合料性质的影响。泡沫沥青胶结料残留水分的存在削弱了泡沫沥青与集料的黏结程度,这对混合料的水稳定性具有不利影响,量化泡沫沥青残留水分对泡沫沥青胶结料性质、泡沫沥青-集料黏附性的影响及提升泡沫温拌沥青混合料抗水损害能力是未来研究的重点。

中图分类号:

- U414

| 1 | 交通运输部.2021年交通运输行业发展统计公报[R]. 北京:交通运输部,2022. |

| 2 | Stroup Gardiner M. Temperature-dependent chemical-specific emission rates of aromatic and polyaromatic hydrocarbons (PAHs) in bitumen fume[J]. Journal of Occupational & Environmental Hygiene, 2007, 4(Sup1): 72-76. |

| 3 | 季节, 徐世法, 罗晓辉. 重复再生沥青混合料及温拌沥青混合料性能评价[M]. 北京: 人民交通出版社,2011. |

| 4 | 拾方治, 孙大权, 罗芳艳, 等. 泡沫沥青混合料物理力学特性的试验研究[J]. 公路, 2004(5): 142-146. |

| Shi Fang-zhi, Sun Da-quan, Luo Fang-yan, et al. Laboratory research on physical and mechanical characteristics of foamed bitumen mixtures[J]. Highway, 2004(5): 142-146. | |

| 5 | 吴英彪, 郭艳芳, 石津金, 等. 泡沫沥青温拌技术在道路工程中的应用[J]. 市政技术, 2011, 29(4): 17-21. |

| Wu Ying-biao, Guo Yan-fang, Shi Jin-jin,et al. Application of warm mix technology based on foamed asphalt in road construction[J]. Municipal Engineering Technology, 2011, 29(4): 17-21. | |

| 6 | Caro S, Masad E, Bhasin A, et al. Moisture susceptibility of asphalt mixtures, part 1: mechanisms[J]. International Journal of Pavement Engineering, 2008, 9(2):81-98. |

| 7 | Cucalon L G, Yin F, Martin A E, et al. Evaluation of moisture susceptibility minimization strategies for warm-mix asphalt: case study[J]. Journal of Materials in Civil Engineering, 2016, 28(2):No.05015002. |

| 8 | Hasan M R M, You Z, Yang X. A comprehensive review of theory, development, and implementation of warm mix asphalt using foaming techniques[J]. Construction & Building Materials, 2017, 152:115-133. |

| 9 | Wasiuddin N M, Selvamohan S, Zaman M M, et al. Comparative laboratory study of sasobit and aspha-min additives in warm-mix asphalt[J]. Transportation Research Record Journal of the Transportation Research Board, 2007, 1998(1):82-88. |

| 10 | Yin F, Arã¡Mbula-Mercado E, Newcomb D. Effect of laboratory foamer on asphalt foaming characteristics and foamed mixture properties[J]. International Journal of Pavement Engineering, 2017, 18(4):358-366. |

| 11 | 韦万峰. 温拌泡沫沥青发泡特性及混合料路用性能研究[D].重庆:重庆交通大学土木工程学院,2018. |

| Wei Wan-feng. Research on foaming characteristics and pavement performance of foamed warm-mix asphalt[D]. Chongqing:School of Civil Engineering, Chongqing Jiaotong University, 2018. | |

| 12 | 李峰, 黄颂昌, 徐剑. 泡沫沥青衰变方程与发泡特性评价[J]. 同济大学学报:自然科学版, 2011, 39(7):1031-1039. |

| Li Feng, Huang Song-chang, Xu Jian.Foamed bitumen decay equation and bitumen foaming characteristics evaluation[J].Journal of Tongji University(Natural Science), 2011, 39(7):1031-1039. | |

| 13 | Abdullah G M S, Wahhab A A. Evaluation of foamed sulfur asphalt stabilized soils for road applications[J]. Construction & Building Materials, 2015, 88:149-158. |

| 14 | Naguib H E, Park C B, Reichelt N. Fundamental foaming mechanisms governing the volume expansion of extruded polypropylene foams[J]. Journal of Applied Polymer Science, 2004, 91(4):2661-2668. |

| 15 | Ozturk H I, Kutay M E. Sensitivity of nozzle-based foamed asphalt binder characteristics to foaming parameters[J]. Journal of the Transportation Research Board, 2014, 2444(1):120-129. |

| 16 | Arega Z A, Bhasin A, Li W, et al. Characteristics of asphalt binders foamed in the laboratory to produce warm mix asphalt[J]. Journal of Materials in Civil Engineering, 2014, 26(11): No.04014078. |

| 17 | 李强, 陈浩,张帅.沥青发泡特性及其影响因素研究[J].公路工程,2019,44(6):62-65. |

| Li Qiang, Chen Hao, Zhang Shuai. Foaming characteristics and factors of asphalt binders [J].Highway Engineering, 2019,44(6) :62-65. | |

| 18 | 李峰, 曾蔚, 徐剑. 沥青发泡特性的优化[J]. 建筑材料学报, 2015, 18(1): 162-167. |

| Li Feng, Zeng Wei, Xu Jian. Optimization of asphalt foaming characteristics[J]. Journal of Building Materials, 2015, 18(1): 162-167. | |

| 19 | 何亮, 王真, 马育, 等. 发泡剂对沥青发泡和混合料水稳定性的影响[J]. 建筑材料学报, 2010, 13(2): 198-202. |

| He Liang, Wang Zhen, Ma Yu,et al. Effect of foaming agent on asphalt foaming and water stability of mixture[J]. Journal of Building Materials, 2010, 13(2): 198-202. | |

| 20 | Newcomb D E, Arambula E, Yin F, et al. Properties of foamed asphalt for warm mix asphalt applications[C]∥NCHRP Report,2015-22145. |

| 21 | Arega Z, Bhasin A, Li W. Parametric analysis of factors that affect asphalt binder foaming characteristics[J]. Journal of Materials in Civil Engineering, 2015,27(12):No.04015052. |

| 22 | Ozturk H I, Kutay M E. Novel testing procedure for assessment of quality of foamed warm mix asphalt binders[J]. Journal of Materials in Civil Engineering, 2014, 26(8):No.0000924. |

| 23 | 尹腾. 可储存式发泡沥青与温拌混合料性能研究[D].南京:东南大学交通学院, 2020. |

| Yin Teng. The study on performances of storable foamed asphalt and warm-mix mixture[D].Nanjing: School of Transportation, Southeast University, 2020. | |

| 24 | Hailesilassie B W, Hugener M, Bieder A, et al. New experimental methods for characterizing formation and decay of foam bitumen[J]. Materials & Structures, 2016, 49(6):2439-2454. |

| 25 | Hailesilassie B W, Schuetz P, Jerjen I, et al. Dynamic X-ray radiography for the determination of foamed bitumen bubble area distribution[J]. Journal of Materials Science, 2015, 50(1):79-92. |

| 26 | Yu X, Liu S, Dong F. Comparative assessment of rheological property characteristics for unfoamed and foamed asphalt binder[J]. Construction & Building Materials, 2016, 122:354-361. |

| 27 | Dong F, Yu X, Liang X, et al. Influence of foaming water and aging process on the properties of foamed asphalt[J]. Construction & Building Materials, 2017, 153:866-874. |

| 28 | 张银宣. 泡沫沥青胶浆的流变特性、微观结构及热特性研究[D].大连:大连海事大学交通运输工程学院,2018. |

| Zhang Yin-xuan. Study on rheological properties,microstructure and thermal properties of foamed asphalt mortar[D]. Dalian: College of Transportation Engineering, Dalian Maritime University, 2018. | |

| 29 | 刘圣洁,谢政专,彭爱红.泡沫温拌沥青的玻璃态转变温度及低温性能[J].深圳大学学报:理工版,2021,38(2):163-169. |

| Liu Sheng-jie, Xie Zheng-zhuan, Peng Ai-hong.Glass transition temperature and low temperature performance for foam warm mix asphalt[J].Journal of Shenzhen University Science and Engineering,2021,38(2): 163-169. | |

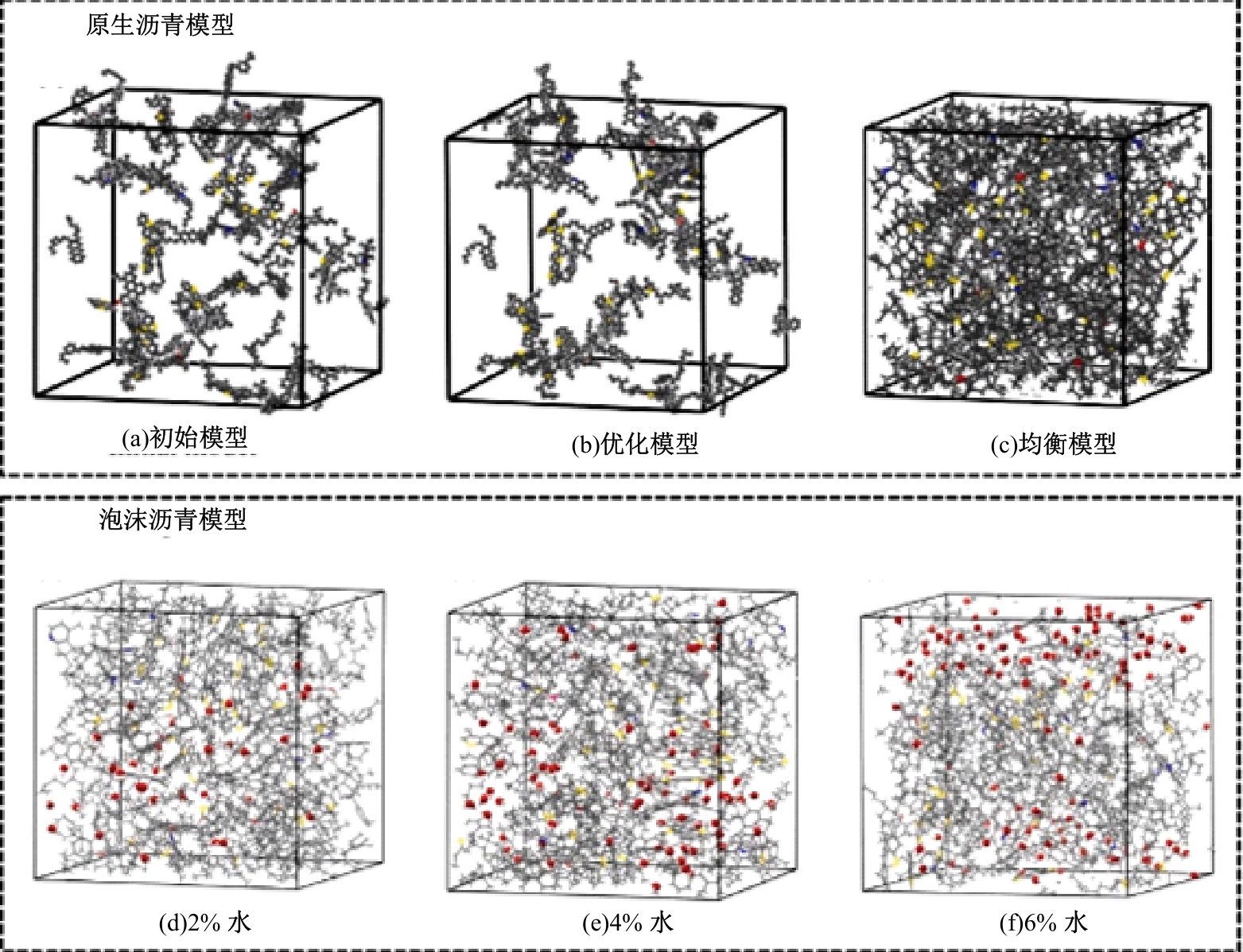

| 30 | 杨健. 基于分子动力学模拟的泡沫沥青-集料界面黏附性研究[D].大连:大连海事大学交通运输工程学院,2022. |

| Yang Jian. Study on adhesion of foamed asphalt - aggregate interface based on molecular dynamics simulation[D]. Dalian: College of Transportation Engineering, Dalian Maritime University, 2022. | |

| 31 | Newcomb D E, Arambula E, Yin F, et al. Properties of foamed asphalt for warm mix asphalt applications[C]∥NCHRP Report, 2015-22145. |

| 32 | Hailesilassie B W, Hugener M, Part M N. Influence of foaming water content on foam asphalt mixtures[J]. Construction & Building Materials, 2015, 85:65-77. |

| 33 | Yao H, Liu J, Wang Y . et al .Mechanism exploration of the foamed asphalt binder using the molecular dynamics(MD) method[J]. Journal of Cleaner Production, 2022 (374):No.134015. |

| 34 | Bairgi B K, Mannan U A, Tarefder R A. Influence of foaming on tribological and rheological characteristics of foamed asphalt[J]. Construction and Building Materials, 2019(205):186-195. |

| 35 | He Y, Wang Q, Zhang J, et al. Foamed crumb rubber asphalt binder: preparation, rheological properties and adhesion characteristics[J]. Journal of Cleaner Production, 2023(396): No.136516. |

| 36 | Maciejewski K, Chomicz-Kowalska A, Remisova E. Effects of water-foaming and liquid warm mix additive on the properties and chemical composition of asphalt binders in terms of short term ageing process[J]. Construction and Building Materials, 2022(341):No. 127756. |

| 37 | Hu J, Ma T, Yin T, et al. Foamed warm mix asphalt mixture containing crumb rubber: foaming optimization and performance evaluation[J]. Journal of Cleaner Production, 2022(333):No.130085. |

| 38 | Liu S, Zhou S, Peng A. Analysis of moisture susceptibility of foamed warm mix asphalt based on cohesion, adhesion, bond strength, and morphology[J]. Journal of Cleaner Production, 2020(277):No.123334. |

| 39 | 邹晓勇, 李英涛, 柏宁. 温拌泡沫沥青混合料不同施工阶段发泡水含量变化规律研究[J]. 中外公路, 2016(2):218-221. |

| Zou Xiao-yong, Li Ying-tao, Bai Ning. Study on the change rule of foam water content in warm mix asphalt mixture at different construction stages[J]. Journal of China and Foreign Highway, 2016(2):218-221. | |

| 40 | Huang B, Zhang Y, Shu X, et al. Neutron scattering for moisture detection in foamed asphalt[J]. Journal of Materials in Civil Engineering, 2013, 25(7):932-938. |

| 41 | 马士宾, 陈奕, 张彩利,等. 基于显微成像技术的温拌泡沫沥青水分消散规律研究[J]. 中外公路, 2015, 35(1):237-243. |

| Ma Shi-bing, Chen Yi, Zhang Cai-li, et al. Study on moisture dissipation law of warm mixed foam asphalt based on microscopic imaging technology[J].Journal of China and Foreign Highway, 2015, 35(1): 237-243. | |

| 42 | Wu Y, Shi J, Xiao Q, et al. 1H-NMR relaxation and application study of evaporatable water in foamed asphalt[C]∥Geo-China International Conference, Shandong, China, 2016: 163-171. |

| 43 | .公路工程沥青及沥青混合料试验规程 [S]. |

| 44 | Alvarez A E, Diaz E J, Mejia R A, et al. Optimizing the dose of warm-mix asphalt additives by maximizing the asphalt-aggregate adhesion measured via surface-free energy[J]. Journal of Materials in Civil Engineering,2023,35(2):109-121. |

| 45 | Guo P, Feng Y X, Wei W F, et al. Adhesion of warm-mix recycled asphalt aggregate mixtures based on surface free energy theory[J]. Journal of Materials in Civil Engineering, 2019,31(10):356-342. |

| 46 | Zeng Z, Zhang D R, Liu H Q. Development of an energy-based framework to determine the surface free energy of asphalt binder: theoretical models[J]. Materials and Structures, 2021,54(6):56-71. |

| 47 | Lytton R L, Masad E A, Zollinger C J, et al.Measurements of surface energy and its relationship to moisture damage[C]∥Transportation Research Record annual Meeting, Washington D.C.,USA, 2003:No.0-4524-2. |

| 48 | Zhu J, Zhang K, Liu K, et al. Adhesion characteristics of graphene oxide modified asphalt unveiled by surface free energy and AFM-scanned micromorphology[J]. Construction and Building Materials,2020,244: No.118404. |

| 49 | 李波,张智豪,刘祥,等.基于表面理论的温拌SBS改性沥青-集料体系的粘附性[J].材料导报,2017,31(4):115-120. |

| Li Bo, Zhang Zhi-hao, Liu Xiang,et al. Adhesion in SBS modified asphalt containing warm mix additive an aggregate system based on surface free theory[J]. Materials Reports, 2017,31(4):115-120. | |

| 50 | 耿九光, 兰倩, 刘光军, 等.基于表面能理论的破碎卵石与沥青粘附性能研究[J].材料导报, 2017, 31(4): 115-120. |

| Geng Jiu-guang, Lan Qian, Liu Guang-jun,et al. Study on adhesion properties of broken pebble and asphalt based on surface energy theory[J]. Materials Reports, 2017, 31(4): 115-120. | |

| 51 | 王岚, 罗学东, 张琪, 等. 温拌胶粉改性沥青-集料粘附性及其体系水稳定性分析[J]. 材料导报,2022, 36(8): 123-130. |

| Wang Lan, Luo Xue-dong, Zhang Qi,et al. Analysis of adhesion of warm mix rubber powder modified asphalt aggregates and water stability of the system[J]. Materials Reports, 2022, 36(8):123-130. | |

| 52 | Sun Z L, Guo Y X, Liu S.Moisture susceptibility evaluation of zeolite-foamed asphalts based on the surface free energy (SFE) concept[J]. Construction and Building Materials, 2023,(371):No.130762. |

| 53 | Diab A, You Z, Ghabchi R, et al. Effects of regular-sized and nanosized hydrated lime on binder rheology and surface free energy of adhesion of foamed warm mix asphalt[J]. Journal of Materials in Civil Engineering, 2014, 27(9): No.0001222. |

| 54 | Huang T, He H W, Zhang P, et al. Laboratory investigation on performance and mechanism of polyphosphoric acid modified bio-asphalt[J]. Journal of Cleaner Production, 2022(333): No.130104. |

| 55 | Meng Y J, Wang Z, Lei J C, et al. Study on aging resistance and micro characteristics of bio-asphalt/TLA composite modified asphalt binder[J]. Construction and Building Materials, 2022,359: No.129566. |

| 56 | Nie Y H, Liu Q, Xiang Z H, et al. Performance and modification mechanism of recycled glass fiber of wind turbine blades and SBS composite-modified asphalt[J].Applied Sciences-Basel,2023,13(10):No.6335. |

| 57 | Su M M, Zhou J L, Lu J Z, et al. Using molecular dynamics and experiments to investigate the morphology and micro-structure of SBS modified asphalt binder[J]. Materials Today Communications, 2022(30):No.103082. |

| 58 | Wang M, Xing C W. Evaluation of microstructural features of Buton rock asphalt components and rheological properties of pure natural asphalt modified asphalt[J]. Construction and Building Materials, 2021(267):No.121132. |

| 59 | Roy S, Hossain Z. Nanoscale quantification of moisture susceptibility of paving asphalts[J]. Matec Web of Conferences, EDP Sciences, 2019,271(1):No.03005. |

| 60 | Santos S D, Part M N, Poulikakos L D.Newly observed effects of water on the microstructures of bitumen surface[J]. Construction and Building Materials,2014, 71:No.618-627. |

| 61 | Sun W, Wang H. Moisture effect on nanostructure and adhesion energy of asphalt on aggregate surface: a molecular dynamics study[J]. Applied Surface Science, 2020: No.145435. |

| 62 | Horcas I, Fernandez R, Gomez-Rodriguez J, et al. WSXM: a software for scanning probe microscopy and a tool for nanotechnology[J]. Review of Scientific Instruments,2007,78(1): No.013705. |

| 63 | Khan M A, Kee S H, Pathan A K, et al. Image processing techniques for concrete crack detection: a scientometrics literature review[J]. Remote Sensing,2023, 15(9): No.2400. |

| 64 | Liu Z, Gu X Y, Dong X Y, et al. Mechanism and performance of graphene modified asphalt: an experimental approach combined with molecular dynamic simulations [J]. Case Studies in Construction Materials, 2023(18):No.e01749. |

| 65 | Sun G Q, Zhang J P, Chen Z X,et al. Interfacial performance of asphalt-aggregate system under different conditions based on molecular dynamics simulation [J]. Journal of Materials in Civil Engineering, 2023,35(6): No.04023116. |

| 66 | Tang Y J, Fu Z, Ma F, et al. Carbon nanotubes for improving rheological and chemical properties of styrene-butadiene-styrene modified asphalt binder[J]. International Journal of Pavement Engineering, 2023,24(1): No.2211212. |

| 67 | Zhu Y J, Ma T, Xu G J,et al. Study of the mixing between asphalt and rejuvenator in hot in-place recycled layer[J]. Journal of Transportation Engineering Part B—Pavements, 2023,149(2): No.04023005. |

| 68 | He L, Li G, Lyu S, et al. Self-healing behavior of asphalt system based on molecular dynamics simulation [J]. Construction and Building Materials, 2020, 254: No.119225. |

| 69 | Chen Z, Yi J, Zhao H, et al. Strength development and deterioration mechanisms of foamed asphalt cold recycled mixture based on MD simulation[J]. Construction and Building Materials,2021, 269: No.121324. |

| 70 | 杨健,郭乃胜,郭晓阳,等.基于分子动力学的泡沫沥青-集料界面黏附性研究[J].材料导报,2021,35():138-144. |

| Yang Jian, Guo Nai-sheng, Xiao-yang Cuo,et al. Adhesion of foamed asphalt-aggregate interface based on molecular dynamics[J]. Materials Reports, 2021, 35(Sup.2): 138-144. | |

| 71 | 唐宁, 王弘晔, 符聃, 等. 沥青混合料温拌技术的研究进展[J]. 中国材料进展, 2020, 39(9): 653-660. |

| Tang Ning, Wang Hong-ye, Fu Dan, et al. Research progress on warm mix asphalt technologies[J]. Materials China,2020,39(9):653-660. | |

| 72 | 梁波, 张海涛, 梁缘, 等.温拌沥青技术研究综述[J].交通运输工程学报, 2023, 23(2): 24-46. |

| Liang Bo, Zhang Hai-tao, Liang Yuan, et al. Review on warm mixing asphalt technology[J].Journal of Traffic and Transportation Engineering, 2023, 23(2):24-46. | |

| 73 | 厉天晗. 泡沫沥青温拌SAC-20混合料水稳性研究[D].重庆: 重庆交通大学土木工程学院, 2018. |

| Li Tian-han. Research on moisture susceptibility of SAC-20 mixture based on foamed asphalt mixing technology[D].Chongqing:School of Civil Engineering, Chongqing Jiaotong University,2018. | |

| 74 | 张智. 高RAP掺量SBS改性沥青泡沫温拌再生混合料配合比设计及耐久性能评价[J]. 公路工程,2016, 41(6): 150-154, 163. |

| Zhang Zhi. Study on design method and durability of SBS modified asphalt foamed warm reclaimed mixture with high RAP content[J]. Highway Engineering, 2016,41(6):150-154, 163. | |

| 75 | 于强. 水发泡温拌再生沥青混合料的水稳定性研究[D].苏州: 苏州科技学院土木工程学院, 2015. |

| Yu Qiang. Moisture susceptbility of water-foaming warm asphalt containing reclaimed asphalt pavement(RAP)[D]. Suzhou:School of Civil Engineering, Suzhou University of Science and Technology,2015. | |

| 76 | 王英, 李萍, 念腾飞, 等.基于动水冲刷作用的沥青混合料短期水损害特性[J]. 吉林大学学报: 工学版, 2020, 50(1): 174-182. |

| Wang Ying, Li Ping, Teng-fei Nian, et al. Short-term water damage characteristics of asphalt mixture based on dynamic water scour effect[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 174-182. | |

| 77 | 陈栩, 曹超飞, 尚静, 等. 动静水环境作用下级配离析对沥青混合料水损害的影响评价[J]. 吉林大学学报: 工学版, 2023, 53(1): 210-219. |

| Chen Xu, Cao Chao-fei, Shang Jing,et al. Evaluation of influence of gradation segregation on pavement moisture damage under action of dynamic and static water environment[J].Journal of Jilin University(Engineering and Technology Edition), 2023,53(1):210-219. |

| [1] | 崔亚宁,司春棣,凡涛涛,王飞. 水-荷耦合作用下沥青桥面铺装层裂缝扩展分析[J]. 吉林大学学报(工学版), 2024, 54(7): 1988-1996. |

| [2] | 高英力,谷小磊,廖美捷,胡新浪,谢雨彤. SiO2气凝胶/反应性弹性体三元共聚物/多聚磷酸复合改性沥青流变性能与改性机理[J]. 吉林大学学报(工学版), 2024, 54(7): 1978-1987. |

| [3] | 徐永丽,杨煦兰,周吉森,杨松翰,孙明刚. 温拌沥青的沥青烟成分及温拌剂抑烟性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1701-1707. |

| [4] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [5] | 赵晓康,胡哲,牛振兴,张久鹏,裴建中,温永. 基于非均质模型的水稳碎石材料细观开裂行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1258-1266. |

| [6] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [7] | 徐进,陈正欢,廖祺硕,郑展骥,张河山. 基于心电数据的高速公路高密度互通立交驾驶负荷[J]. 吉林大学学报(工学版), 2024, 54(10): 2807-2818. |

| [8] | 朱洪洲,苏春力,唐乃膨,魏俊尧,孙宏军. 胶粉改性沥青排放物采样及定量分析方法[J]. 吉林大学学报(工学版), 2024, 54(10): 2922-2929. |

| [9] | 陈俊,孙振浩,赵成,吴欣怡,王俊鹏. 相变沥青混凝土复合结构降温效果试验分析[J]. 吉林大学学报(工学版), 2024, 54(1): 180-187. |

| [10] | 唐乃膨,薛晨阳,刘少鹏,朱洪洲,李睿. 胶粉改性沥青老化机理及表征评价研究综述[J]. 吉林大学学报(工学版), 2024, 54(1): 22-43. |

| [11] | 王壮,冯振刚,姚冬冬,崔奇,沈若廷,李新军. 导电沥青混凝土研究进展[J]. 吉林大学学报(工学版), 2024, 54(1): 1-21. |

| [12] | 赵胜前,丛卓红,游庆龙,李源. 沥青-集料黏附和剥落研究进展[J]. 吉林大学学报(工学版), 2023, 53(9): 2437-2464. |

| [13] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [14] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [15] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

|

||