吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (5): 1552-1558.doi: 10.13229/j.cnki.jdxbgxb.20230865

裂解槽深度对减速器壳体轴承座裂解性能的影响

- 吉林大学 材料科学与工程学院,长春 130022

Influence of cracking groove depth on cracking performance of bearing seat of reducer housing

Yong ZHAO( ),Wen-ming JIN,Qi-feng ZHENG(

),Wen-ming JIN,Qi-feng ZHENG( ),Shu-qing KOU

),Shu-qing KOU

- School of Materials Science and Engineering,Jilin University,Changchun 130022,China

摘要:

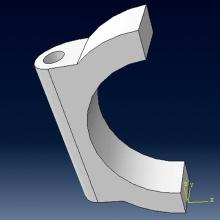

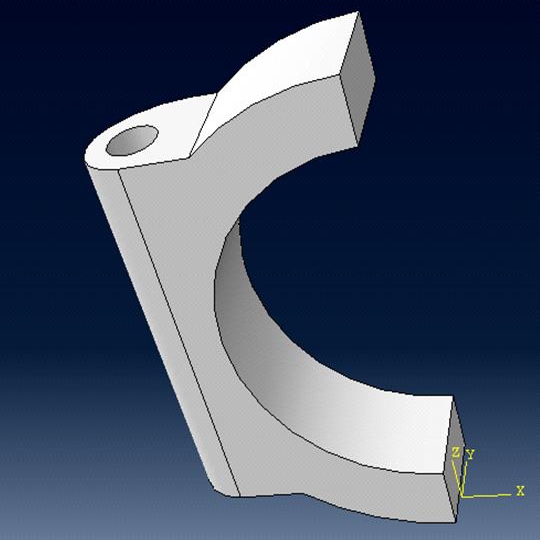

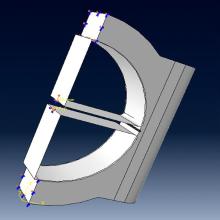

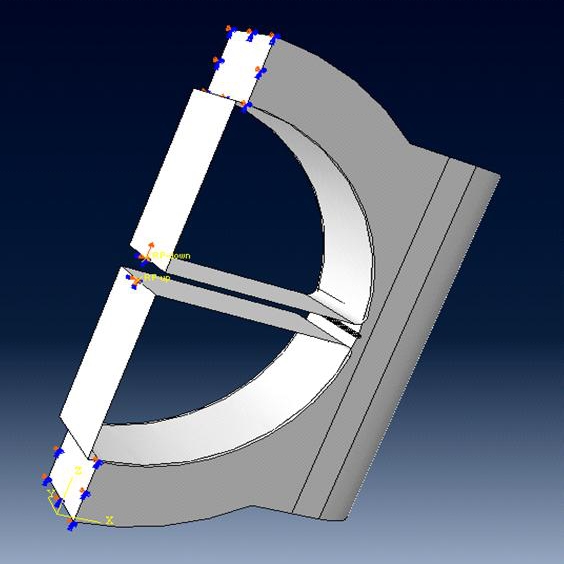

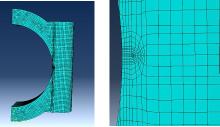

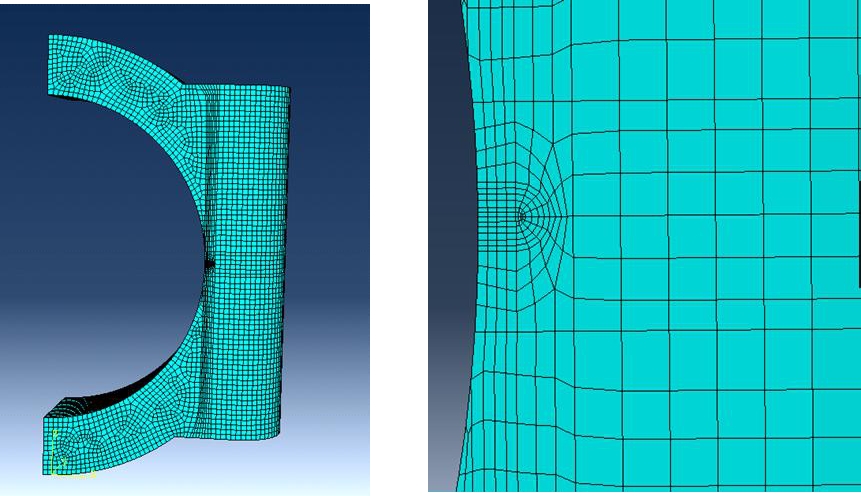

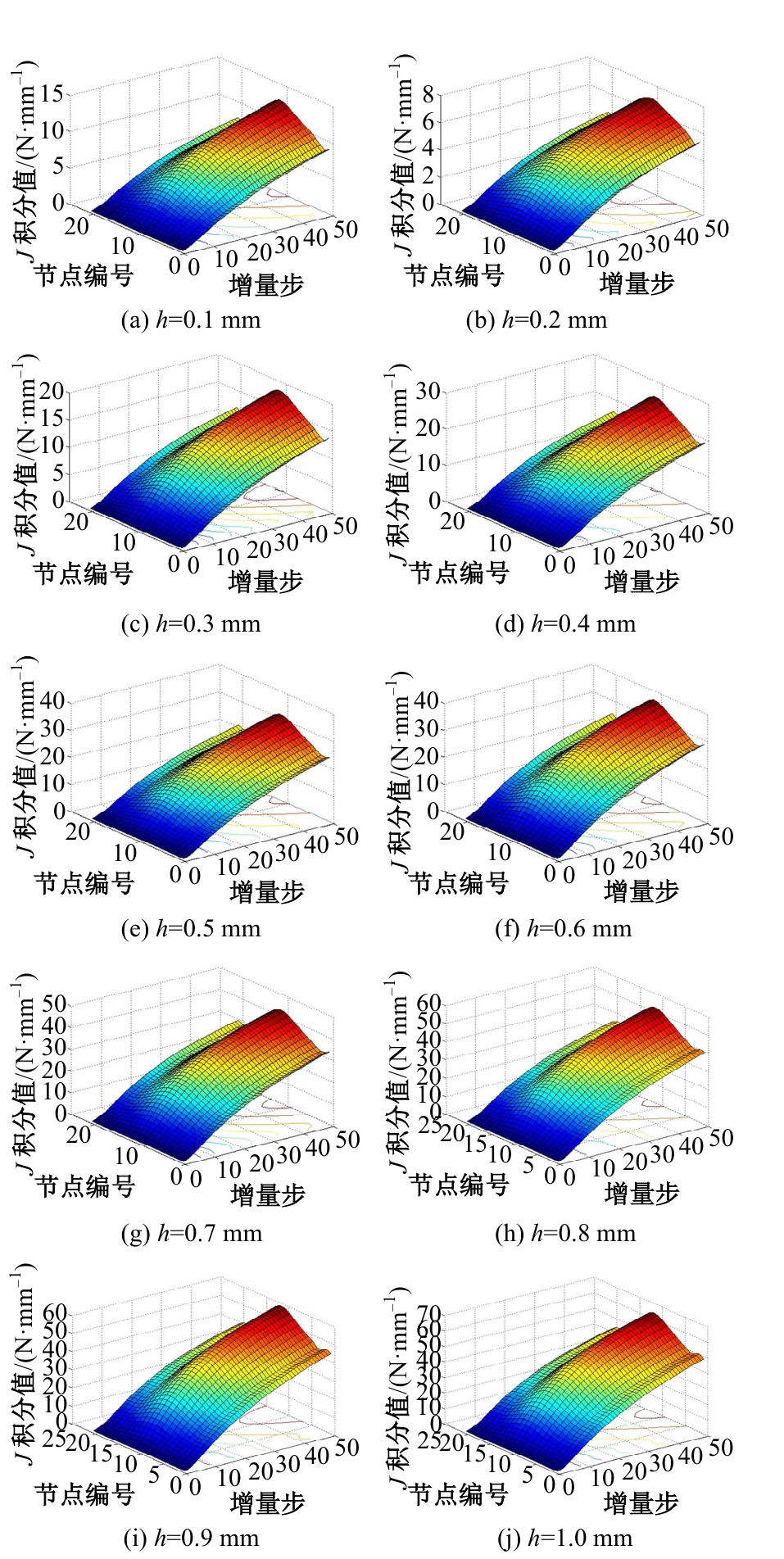

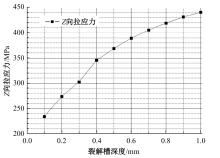

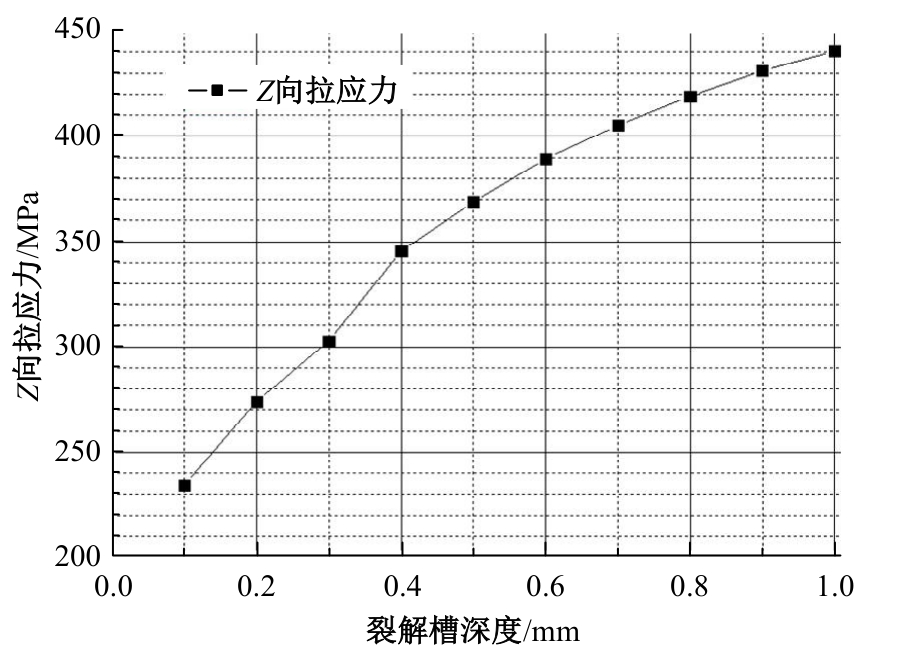

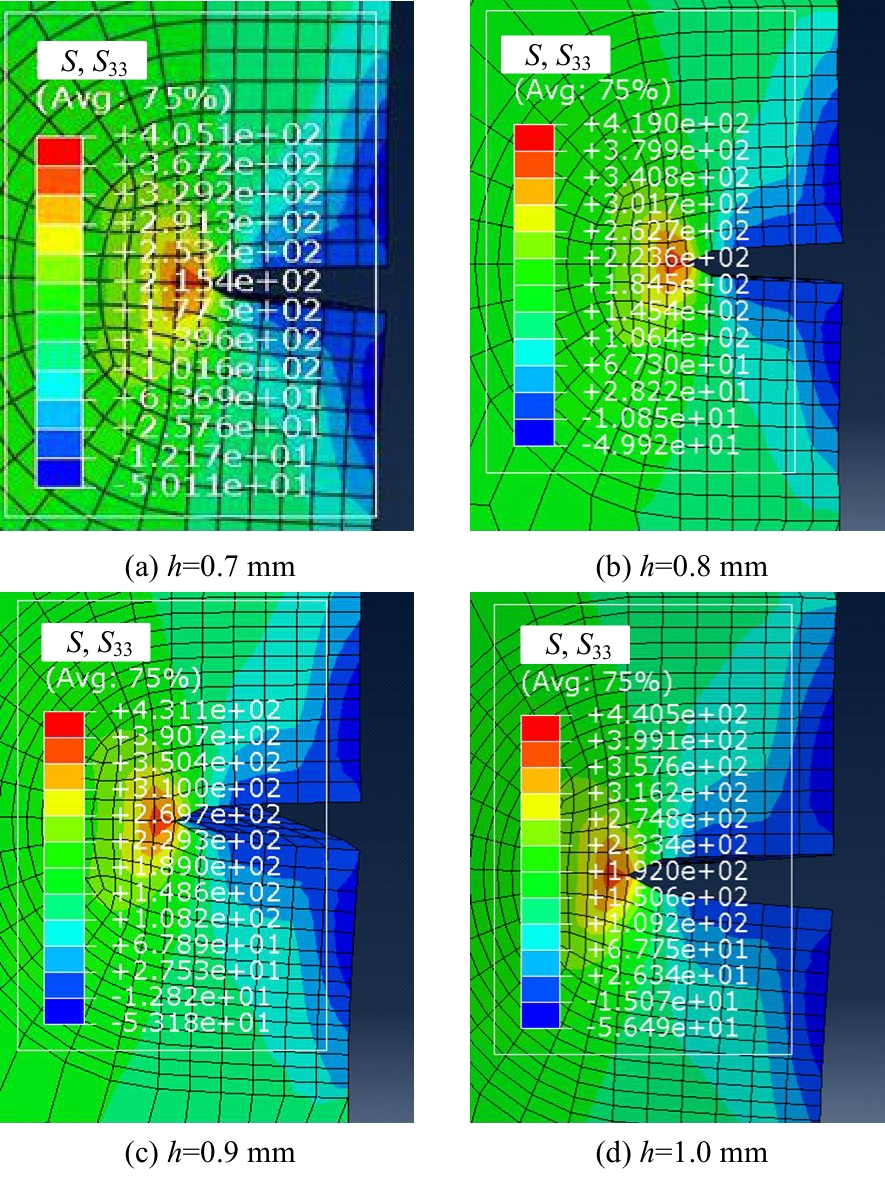

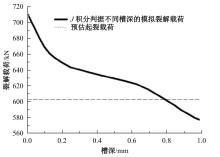

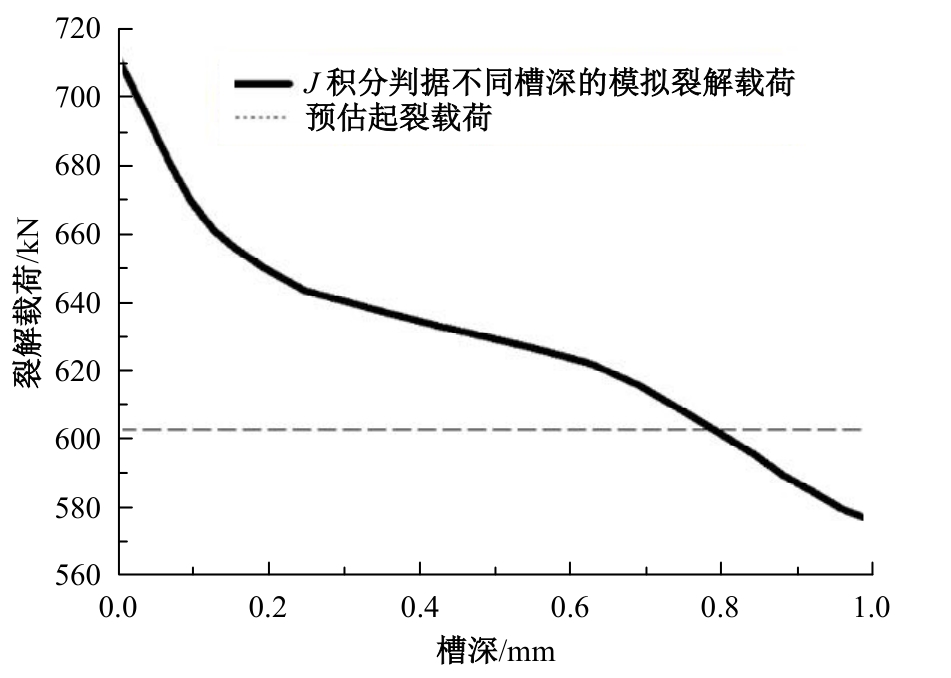

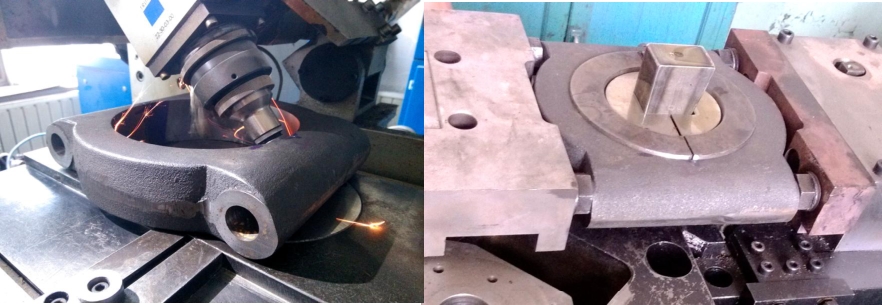

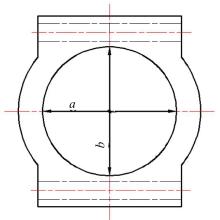

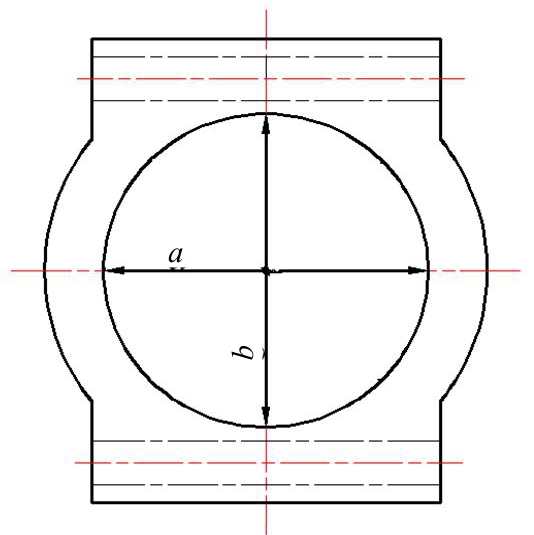

采用ABAQUS进行了后桥减速器壳体轴承座裂解起裂模拟,通过J积分和裂解槽尖端Z向拉应力探究了激光预制裂解槽深度对裂解载荷和变形的影响规律,结果表明:裂解槽在轴承座厚度中间面位置面对应节点的J积分在不同槽深的整个模拟加载过程中保持最大,裂解起裂在此位置发生;参考连杆裂解预估壳体轴承座裂解裂载荷603 kN时,槽深大于0.7 mm情况下轴承座厚度中间面位置面对应节点的模拟最大拉应力超过抗拉强度,裂解起裂发生,起裂时壳体轴承座仅仅在裂解槽起裂位置局部微小区域进入塑性状态;根据J积分判据确定了不同裂解槽深度的模拟裂解载荷,绘制和拟合了裂解槽深度和载荷曲线,603 kN对应槽深为0.797 mm。并对激光预制1.0 mm深度的裂解槽进行裂解实验,实际裂解载荷和模拟裂解载荷误差为4.30%,试件内径变化值为0.16~0.24 mm,小于轴承孔裂解加工允许塑性变形(≤0.4 mm)。综合模拟分析结果并结合实际生产,采用激光加工后桥减速器壳体轴承座裂解槽深度参数范围为0.8~1.0 mm。

中图分类号:

- TK406

| [1] | 陆刚. 重型车驱动桥及其主要部件结构[J]. 商用车与发动机, 2009(47): 74-76. |

| Lu Gang. Driving axle & main parts of heavy commercial vehicle[J]. CVE, 2009(47): 74-76. | |

| [2] | 姚为民. 汽车构造下[M]. 北京:机械工业出版社,2022. |

| [3] | 瑞佩尔. 图解汽车变速器原理与构造[M]. 北京:化学工业出版社,2022. |

| [4] | 江业君, 张家政. 后桥主减速器壳体加工工艺探索[J]. 客车技术, 2005(1): 37-38. |

| Jiang Ye-jun, Zhang Jia-zheng. Exploration on processing technology of rear axle main reducer housing[J]. Bus Technology, 2005(1): 37-38. | |

| [5] | 刘景涛. 汽车驱动桥主减速器总成预加载荷研究及系统实现[D]. 杭州: 浙江大学机械与能源工程学院, 2009. |

| Liu Jing-tao.The research of pre-load for main reducer of automobile´s driving axle and the system development[D]. Hangzhou: School of Mechanical and Energy Engineering, Zhejiang University, 2009. | |

| [6] | Zhou S, Kou S Q. Study on fracture-split performance of 36MnVS4 and analysis of fracture-split easily-induced defects[J].Metals,2018,8(9):0809696. |

| [7] | Yang H Q, Kou S Q, Li Z Y,et al. 3D interconnected nitrogen-self-doped carbon aerogels as efficient oxygen reduction electrocatalysts derived from biomass gelatin[J]. RSC Advances, 2019, 69(9): 40301-40308. |

| [8] | Kou S Q, Shi Z, Song W F. Fracture-splitting processing performance study and comparison of the C70S6 and 36MnVS4 connecting rods[J]. SAE International Journal of Engines, 2018, 11(4): 463-474. |

| [9] | 杨慎华, 寇淑清, 何东野,等. 发动机缸体主轴承座裂解槽激光加工设备[P]. 中国: CN200710055511.3. |

| [10] | 王科. 减速器壳体的铸造工艺设计[J]. 汽车知识, 2023, 23(4): 96-98. |

| Wang Ke. Casting process design of reducer shell[J]. Automotive Knowledge,2023,23(4): 96-98. | |

| [11] | 李新宁, 李才儿, 黄桂英, 等. 减速器壳体高速加工技术研究及其应用[J]. 制造技术与机床, 2014(1): 35-38. |

| Li Xin-ning, Li Cai-er, Huang Gui-ying,et al. Research and application of speed- reducer shell's high speed processing technology[J]. Manufacturing Technology & Machine Tool, 2014(1) : 35-38. | |

| [12] | 李金华, 王海涛, 郑敬超. 高端乘用车减速器壳体加工方案[J]. 汽车工艺师, 2015(3): 24-25. |

| Li Jin-hua, Wang Hai-tao, Zheng Jing-chao. Machining scheme of reducer shell for high-end passenger cars[J]. Automotive Engineer, 2015(3): 24-25. | |

| [13] | 孟令健, 张孟枭, 李玉娟,等. 蠕墨铸铁RuT400与RuT450的拉伸与疲劳性能[J]. 上海金属, 2020, 42(4): 18-25. |

| Meng Ling-jian, Zhang Meng-xiao, Li Yu-juan,et al. Tensile and fatigue properties of vermicular graphite cast Irons RuT400 and RuT450[J]. Shanghai Metals,2020, 42(4): 18-25. | |

| [14] | 修亭亭. 后桥减速器壳体轴承座材料裂解性能数值模拟及实验研究[D]. 长春: 吉林大学材料科学与工程学院, 2020. |

| Xiu Ting-ting. Numerical simulation and experimental study on materialfracture splitting performance of rear axles'reducershell bearing seat[D]. Changchun: College of Materials Science and Engineering, Jilin University,2020. | |

| [15] | 寇淑清, 修亭亭, 金文明,等. 后桥主减速器壳体轴承座材料裂解性能数值分析[J]. 华南理工大学学报: 自然科学版, 2019, 47(7): 121-127. |

| Kou Shu-qing, Xiu Ting-ting, Jin Wen-ming, et al. Numerical analysis of cracking performance of rear axle main reducer housing bearing housing material[J]. Journal of South China University of Technology(Natural Science Edition), 2019, 47(7): 121-127. | |

| [16] | 赵勇. 基于小范围屈服断裂的连杆胀断参数研究及应用[D]. 长春: 吉林大学材料科学与工程学院, 2011. |

| Zhao Yong. Study on parameters of connecting rod fracture splitting based on fracture after small scale yielding and its application[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2011. |

| [1] | 吴金星,马宇翔,肖嘉邦,徐耀,李松歌. H型翅片椭圆管壁面磨损特性的数值模拟[J]. 吉林大学学报(工学版), 2024, 54(9): 2495-2501. |

| [2] | 何华飞,李兆平,符瑞安,马绍麟,黄明利. 考虑地层约束效应的预制侧墙节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1601-1611. |

| [3] | 娄淑梅,李一明,李鑫,陈鹏,白雪峰,程宝嘉. 基于BP神经网络和Arrhenius本构模型的石墨烯/7075复合材料热变形行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1237-1245. |

| [4] | 赵秋,陈鹏,赵煜炜,余澳. 台后设置拱形结构的无缝桥梁整体受力性能[J]. 吉林大学学报(工学版), 2024, 54(4): 1016-1027. |

| [5] | 李任君,赵一兵,顾莉栋,谭洪强,宋林森,田岩. 应用于车辆质心测量的改进侧倾法[J]. 吉林大学学报(工学版), 2024, 54(11): 3175-3183. |

| [6] | 于征磊,曹青,张钧栋,沙鹏威,金敬福,魏万祯,梁平,张志辉. 基于增材制造的着陆器仿生缓冲结构的力学特性[J]. 吉林大学学报(工学版), 2024, 54(10): 3077-3084. |

| [7] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

| [8] | 郑植,袁佩,金轩慧,魏思斯,耿波. 桥墩复合材料柔性防撞护舷试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2581-2590. |

| [9] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

| [10] | 顾正伟,张攀,吕东冶,吴春利,杨忠,谭国金,黄晓明. 基于数值仿真的简支梁桥震致残余位移分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1711-1718. |

| [11] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [12] | 金敬福,董新桔,贾志成,王康,贺连彬,邹猛,齐迎春. 板簧式弹性金属车轮胎面弹片结构优化[J]. 吉林大学学报(工学版), 2023, 53(4): 964-972. |

| [13] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [14] | 解方喜,赵士杰,王梓森,刘爽,李小平,张程. 多孔喷油器闪急沸腾喷雾坍塌影响因素的仿真分析[J]. 吉林大学学报(工学版), 2023, 53(12): 3314-3325. |

| [15] | 戴理朝,周亮,杨晓文,王磊. 基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报(工学版), 2023, 53(10): 2886-2896. |

|