吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (9): 2483-2492.doi: 10.13229/j.cnki.jdxbgxb.20211236

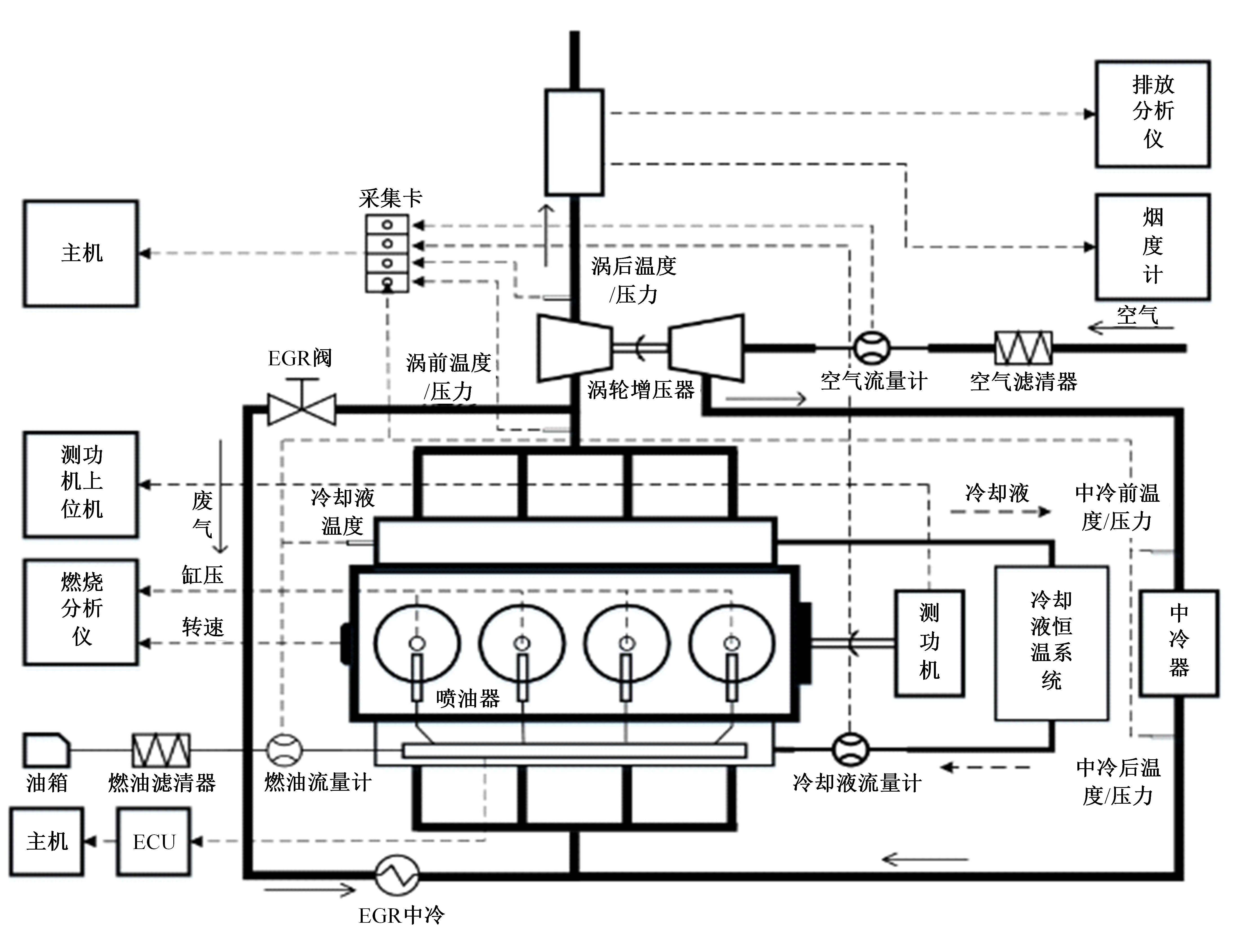

柴油机瞬变工况喷射参数及田口法协同优化对微粒排放的影响

- 1.吉林大学 汽车底盘集成与仿生全国重点实验室,长春 130022

2.吉林大学 汽车工程学院,长春 130022

Effects of injection parameters and taguchi method on particulate emissions of diesel engine under transient conditions

Shuang FENG1,2( ),Wei HONG1,2,Xiao-ping LI1,2(

),Wei HONG1,2,Xiao-ping LI1,2( ),Fang-xi XIE1,2

),Fang-xi XIE1,2

- 1.National Key Laboratory of Automotive Chassis Integration and Bionics,Jilin University,Changchun 130022,China

2.College of Automotive Engineering,Jilin University,Changchun 130022,China

摘要:

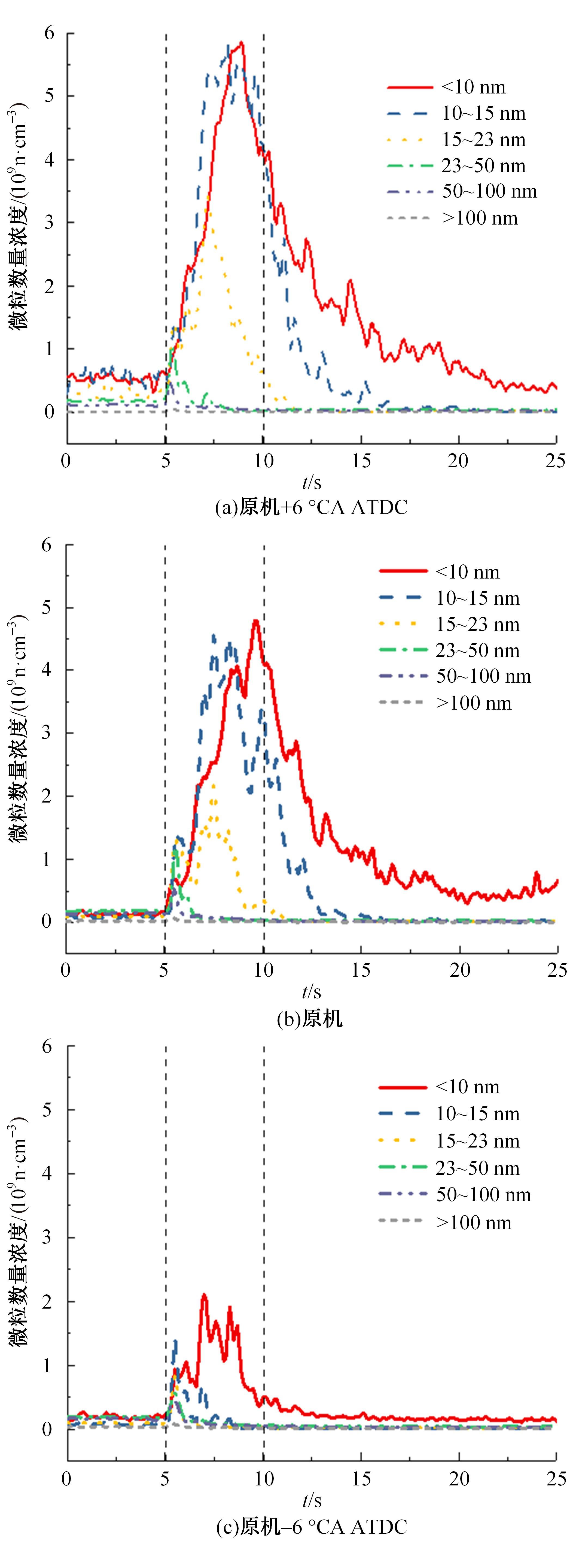

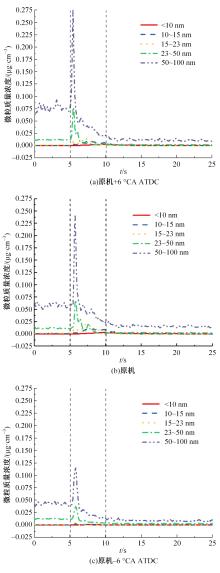

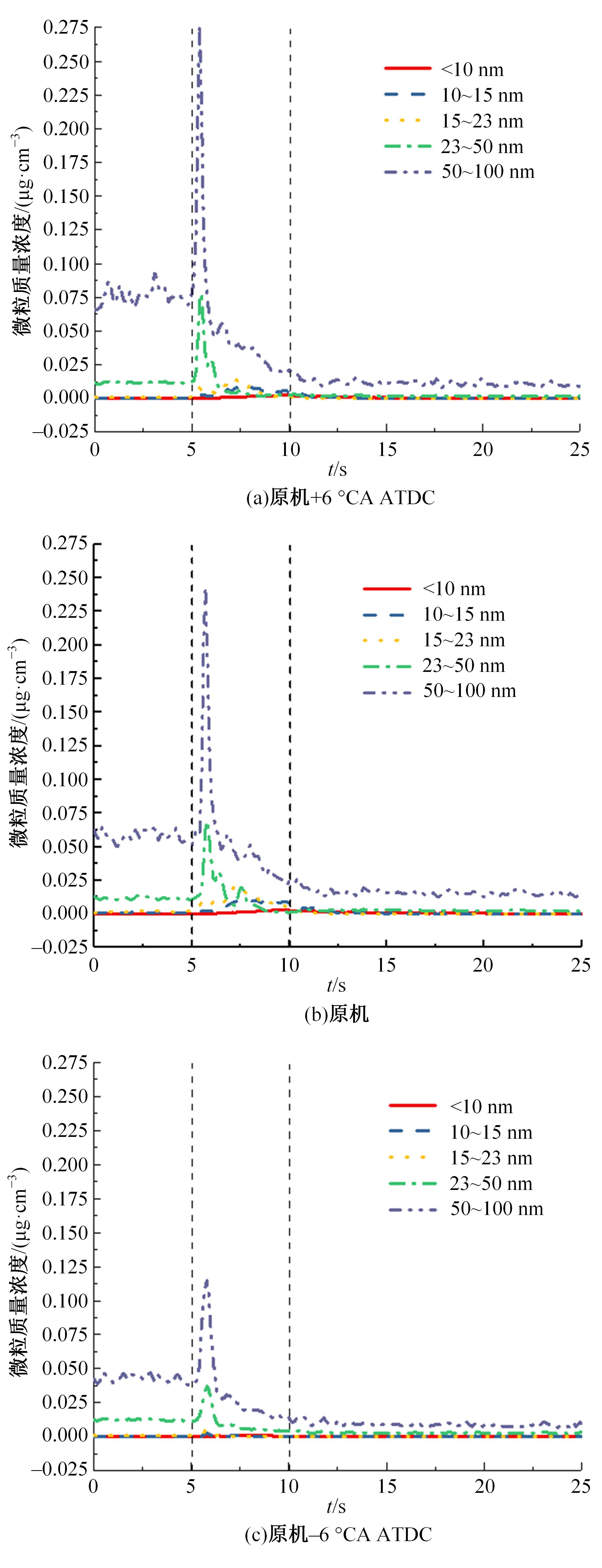

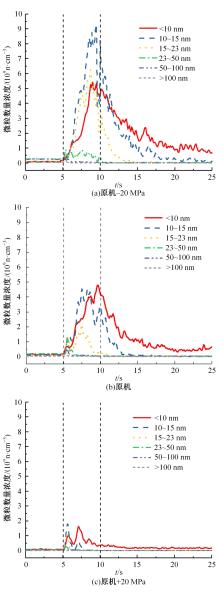

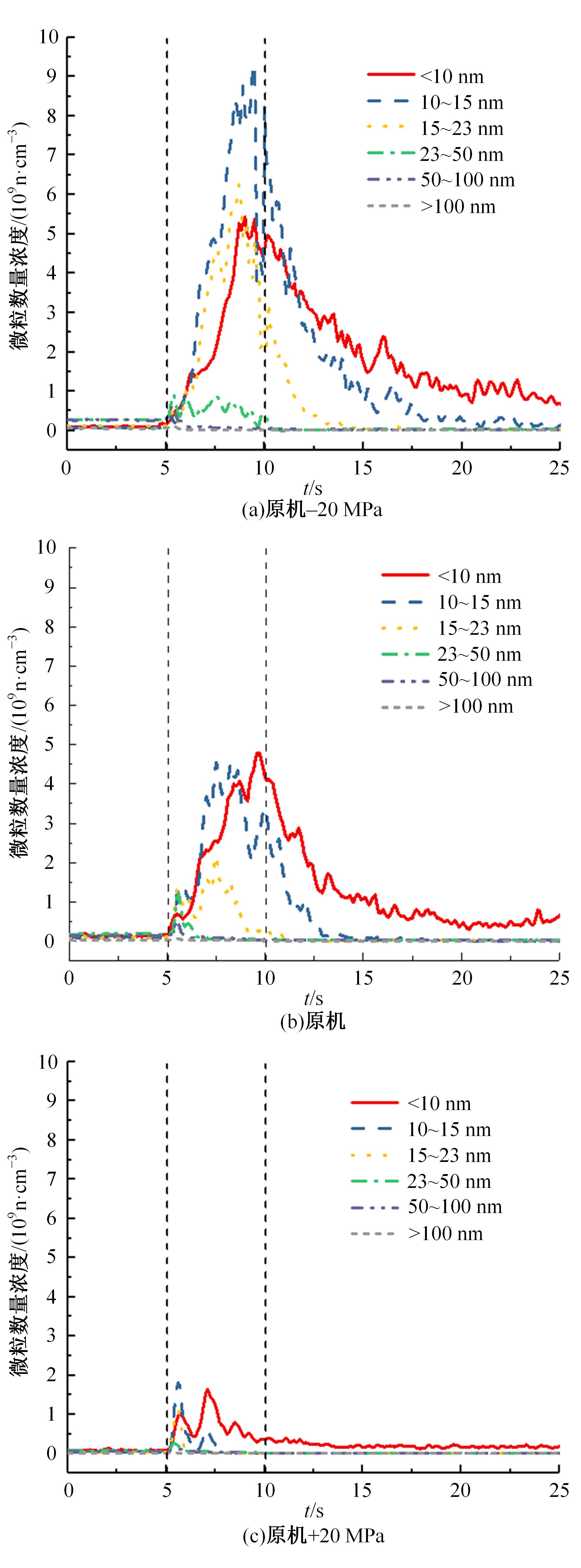

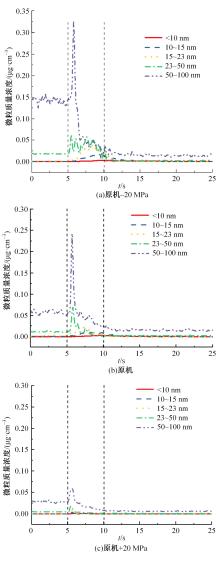

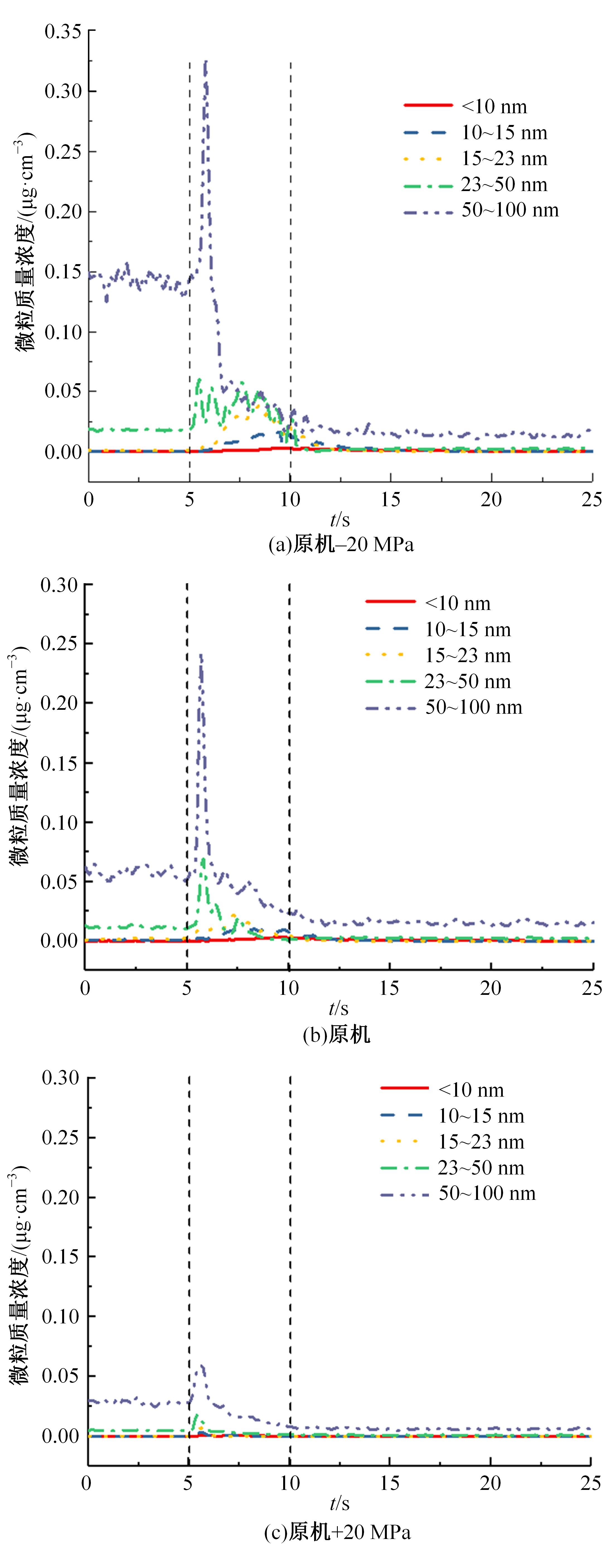

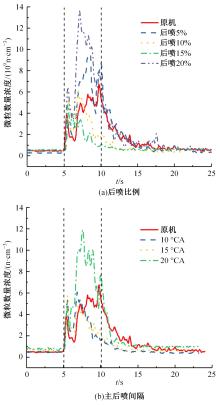

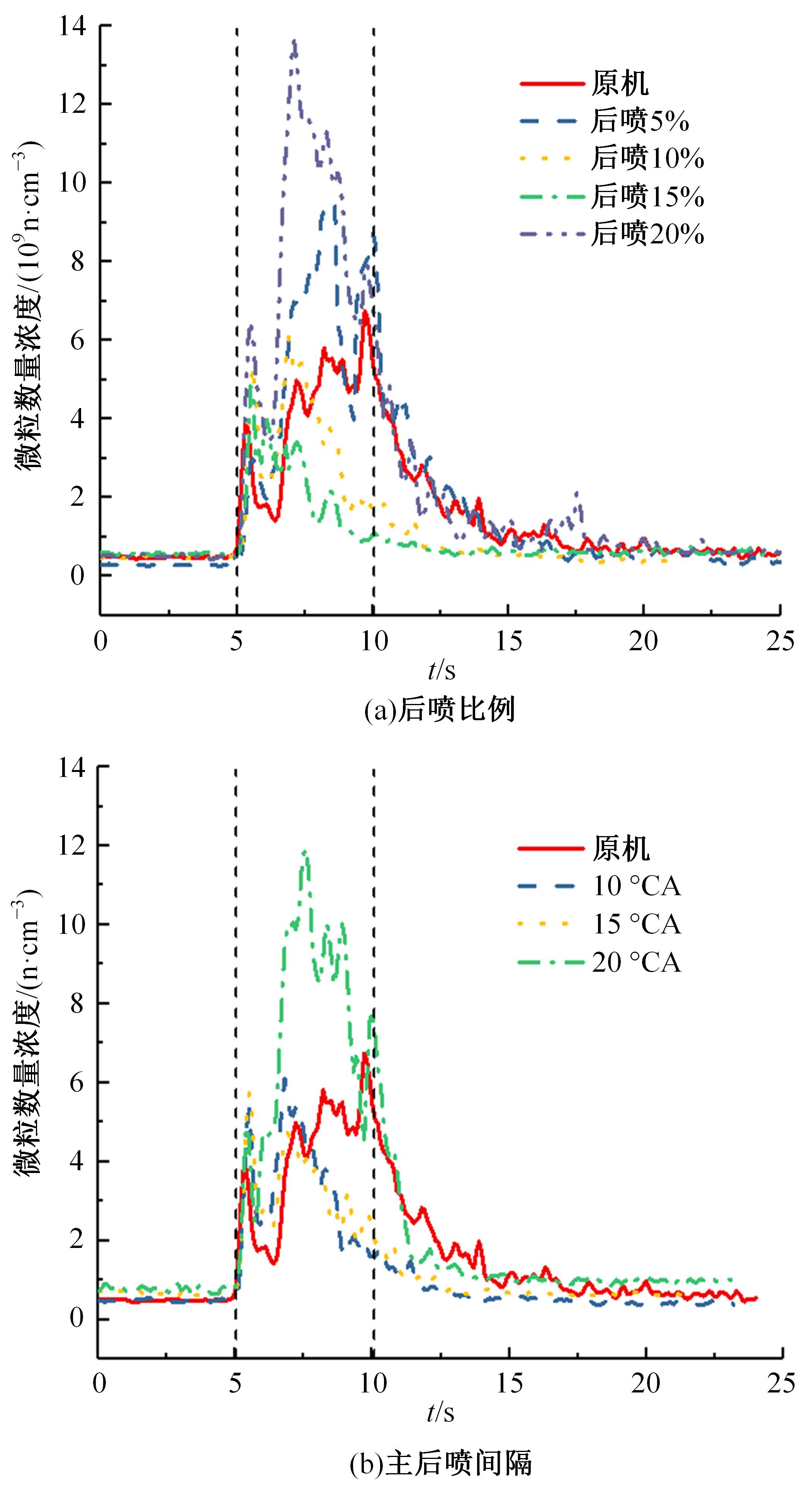

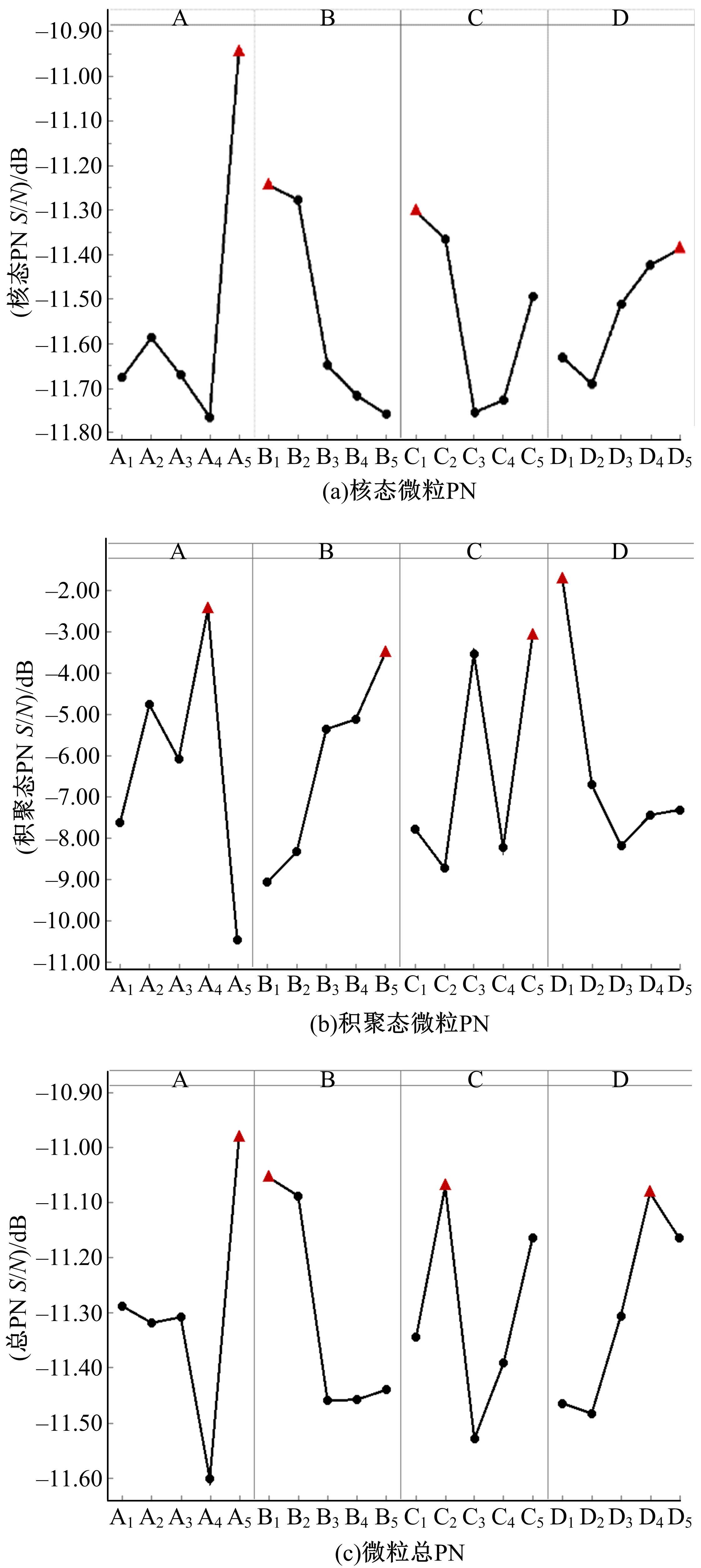

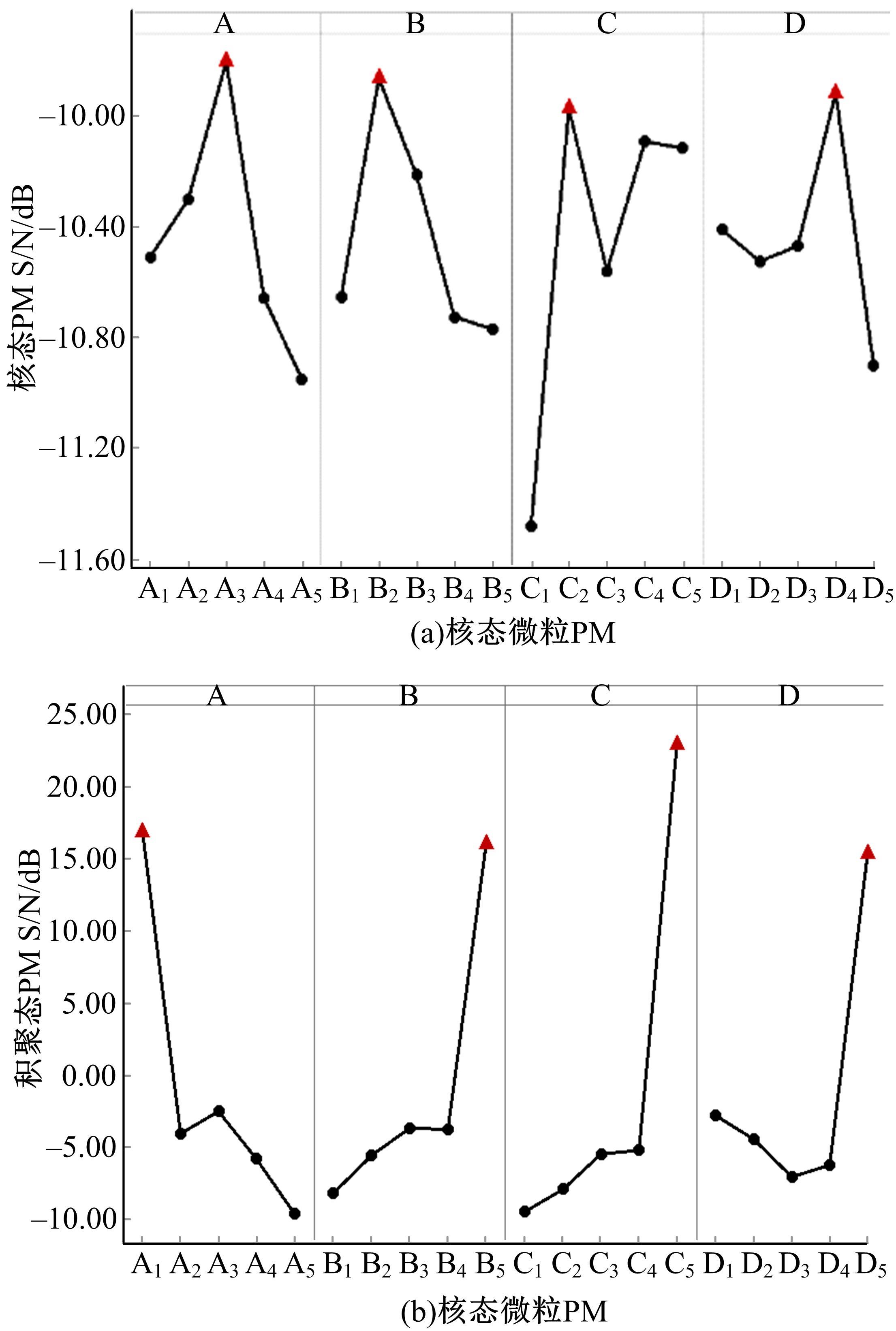

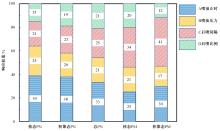

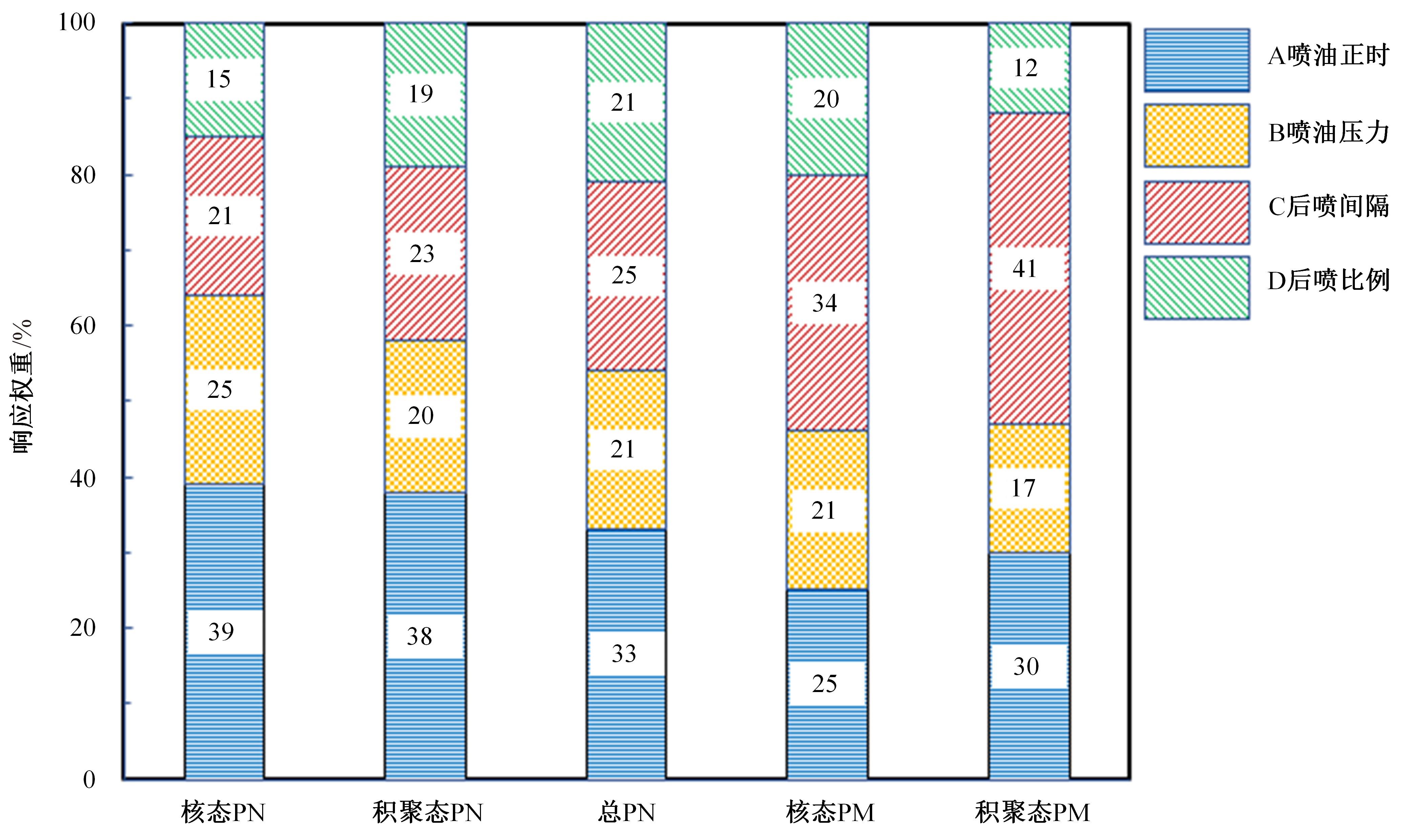

为研究发动机“恒转增扭”瞬变工况下的微粒排放特性及优化方法,以车用2.8 L增压柴油机为研究对象,首先研究了单因素喷射参数对柴油机瞬态加载工况微粒排放的影响;随后设计了田口正交试验,给出以微粒数量及质量为输出指标的最优控制参数组合,并确定了各控制参数的影响权重。结果表明:在瞬变加载过程中,小尺寸核态颗粒物数量浓度恶化明显,大尺寸聚集态颗粒物质量浓度显著恶化;适当地将主喷时刻提前、增大轨压以及引入恰当的后喷可降低微粒排放;同时,控制参数对核态和聚集态微粒的影响存在Trade-off关系,对微粒排放影响权重相对较大的均为喷油时刻的影响,即喷油正时和主后喷间隔。

中图分类号:

- TK421.5

| 1 | Nilsson T, Froberg A, Aslund J. Optimal operation of a turbocharged diesel engine during transients[J] SAE International Journal of Engines, 2012,5(2): 571-578. |

| 2 | 隋菱歌. 增压柴油机瞬态工况性能仿真及优化[D].长春:吉林大学汽车工程学院,2012. |

| Sui Ling-ge. Simulation and optimization of turbo charged diesel engine performance under transient operations[D]. Changchun; College of Automotive Engineering, Jilin University, 2012. | |

| 3 | Rakopoulos C D, Michos C N, Giakoumis E G. Study of the transient behavior of turbocharged diesel engines including compressor surging using a linearized quasi-steady analysis[C]∥SAE Paper, 2005-01-0225. |

| 4 | Rakopoulos C D, GiakoumisE G, Rakopoulos D C. The effect of friction modelling on the prediction of turbocharged diesel engine transient operation[C]∥SAE Paper, 2004-01-0925. |

| 5 | Grahn M, Johansson K, McKelvey T. Model-based diesel engine management system optimization for transient engine operation[J]. Control Engineering Practice, 2014, 29: 103-114. |

| 6 | Atkinson C, Allain M, Zhang H. Using model-based rapid transient calibration to reduce fuel consumption and emissions in diesel engines[C]∥SAE Paper, 2008-01-1365. |

| 7 | Atkinson C, Mott G. Dynamic model-based calibration optimization: an introduction and application to diesel engines[C]∥SAE Paper, 2005-01-0026, 2005. |

| 8 | Liu S, Cui Y, Wang Y, et al. An evaluation method for transient response performance of turbocharged diesel engines[J]. Energy, 2019, 182:852-863. |

| 9 | 付建勤. 车用发动机瞬变工况运行与性能参数连续检测及热功转换过程研究[D]. 长沙:湖南大学机械与运载工程学院, 2014. |

| Fu Jian-qin. Continuous detecting on the operating and performance parameters of automotive engine under transient conditions and study of the heat-work conversion process[D]. Changsha; College of Mechanical and Vehicle Engineering, Hunan University, 2014. | |

| 10 | 张龙平. 车用柴油机瞬变工况性能劣变及其控制策略研究[D]. 长春:吉林大学汽车工程学院,2015. |

| Zhang Long-ping. Investigation of performance deterioration and control strategy of automotive diesel engine under transient operation conditions[D]. Changchun: College of Automotive Engineering, Jilin University, 2015. | |

| 11 | 刘长铖. 车用增压柴油机瞬变过程能量流及㶲流分析[D]. 长春:吉林大学汽车工程学院, 2020. |

| Liu Chang-cheng. Analysis of energy flow, exergy flow and optimization of energy efficiency in an automotive turbocharged diesel engine[D]. Changchun; College of Automotive Engineering, Jilin University, 2020. | |

| 12 | Tan Pi-qiang, Ruan Shuai-shuai, Hu Zhi-yuan, et al. Particle number emissions from a light-duty diesel engine with biodiesel fuels under transient-state operating conditions[J]. Applied Energy, 2014, 113: 22-31. |

| 13 | 谭丕强, 胡志远, 楼狄明, 等. 车用柴油机瞬变工况的排气颗粒数量[J]. 机械工程学报, 2012, 48(14): 134-140. |

| Tan Pi-qiang, Hu Zhi-yuan, Lou Di-ming. Quantity of exhaust particles in vehicle diesel engine under transient conditions[J]. Chinese Journal of Mechanical Engineering, 2012, 48(14): 134-140. | |

| 14 | Sun Wan-chen, Wang Qiao, Guo Liang, et al. Influence of biodiesel/diesel blends on particle size distribution of CI engine under steady/transient conditions[J]. Fuel, 2019, 245: 336-344. |

| 15 | Zhang X B, Wang Z X, Xiao B, et al. A neural network learning-based global optimization approach for aero-engine transient control schedule[J]. Neurocomputing, 2021, 469: 180-188. |

| 16 | Zhang Miao-miao, Hong Wei, Xie Fang-xi, et al. Combustion, performance and particulate matter emissions analysis of operating parameters on a GDI engine by traditional experimental investigation and Taguchi method[J]. Energy Conversion and Management, 2018, 164: 344-352. |

| 17 | Uslu S, Yaman H, Yesilyurt M K. Optimization of parameters affecting the performance and emissions of a spark ignition engine fueled with n-pentanol/gasoline blends using taguchi method[J]. Arabian Journal for Science and Engineering, 2021, 46(12): 11711-11724. |

| [1] | 焦玉玲,邓雪,李琳,刘文佳,张天泽,曹楠. 多约束条件下双边U型装配线平衡与协同优化[J]. 吉林大学学报(工学版), 2023, 53(7): 2053-2060. |

| [2] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [3] | 刘洋,刘吉成. 基于大数据与粒子群的清洁能源协同优化调度方法[J]. 吉林大学学报(工学版), 2023, 53(5): 1443-1448. |

| [4] | 马苗苗,刘立成,王鑫,杨茂. 风光发电与新能源汽车协同优化调度策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2096-2106. |

| [5] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [6] | 高文志,王彦军,王欣伟,张攀,李勇,董阳. 基于卷积神经网络的柴油机失火故障实时诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 417-424. |

| [7] | 苏岩,王博,刘宇,解方喜,胡云峰,段加全. 柴油喷射时刻及汽油比例对均质混合气引燃模式排放性能的影响[J]. 吉林大学学报(工学版), 2022, 52(1): 37-45. |

| [8] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [9] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

| [10] | 王乔,孙万臣,郭亮,程鹏,范鲁艳,李国良. 丁醇/柴油混合燃料对压燃式发动机燃烧及微粒排放特征的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1920-1928. |

| [11] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [12] | 祖象欢,杨传雷,王贺春,王银燕. 船用柴油机废气再循环性能评估及应用[J]. 吉林大学学报(工学版), 2019, 49(3): 805-815. |

| [13] | 杨帅, 冯志炜, 赵治国, 周毅. 不同米勒循环方式对柴油机工作过程影响的一维模拟分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1444-1454. |

| [14] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

| [15] | 田径, 刘忠长, 刘金山, 董春晓, 钟铭, 杜文畅. 基于燃烧边界参数响应曲面设计的柴油机性能优化[J]. 吉林大学学报(工学版), 2018, 48(1): 159-165. |

|